Orlando, Florida, USA – January 2026 — During the 50th anniversary celebration of Surf Expo at the Orange County Convention Center in Orlando, ARKKY exhibited and showcased its 3D-printed footwear lineup. The event brought together professionals from retail, distribution, and brand sectors for discussions centered on material applications, production efficiency, and supply chain optimization.

ARKKY representative stated that its primary objective for participating in the expo was to demonstrate to the industry the viability of 3D-printed footwear in scaled production and real-world commercial applications, while also engaging in discussions and building connections with potential partners.

AIHALS Technology: Emphasizing Manufacturing Efficiency and Stability

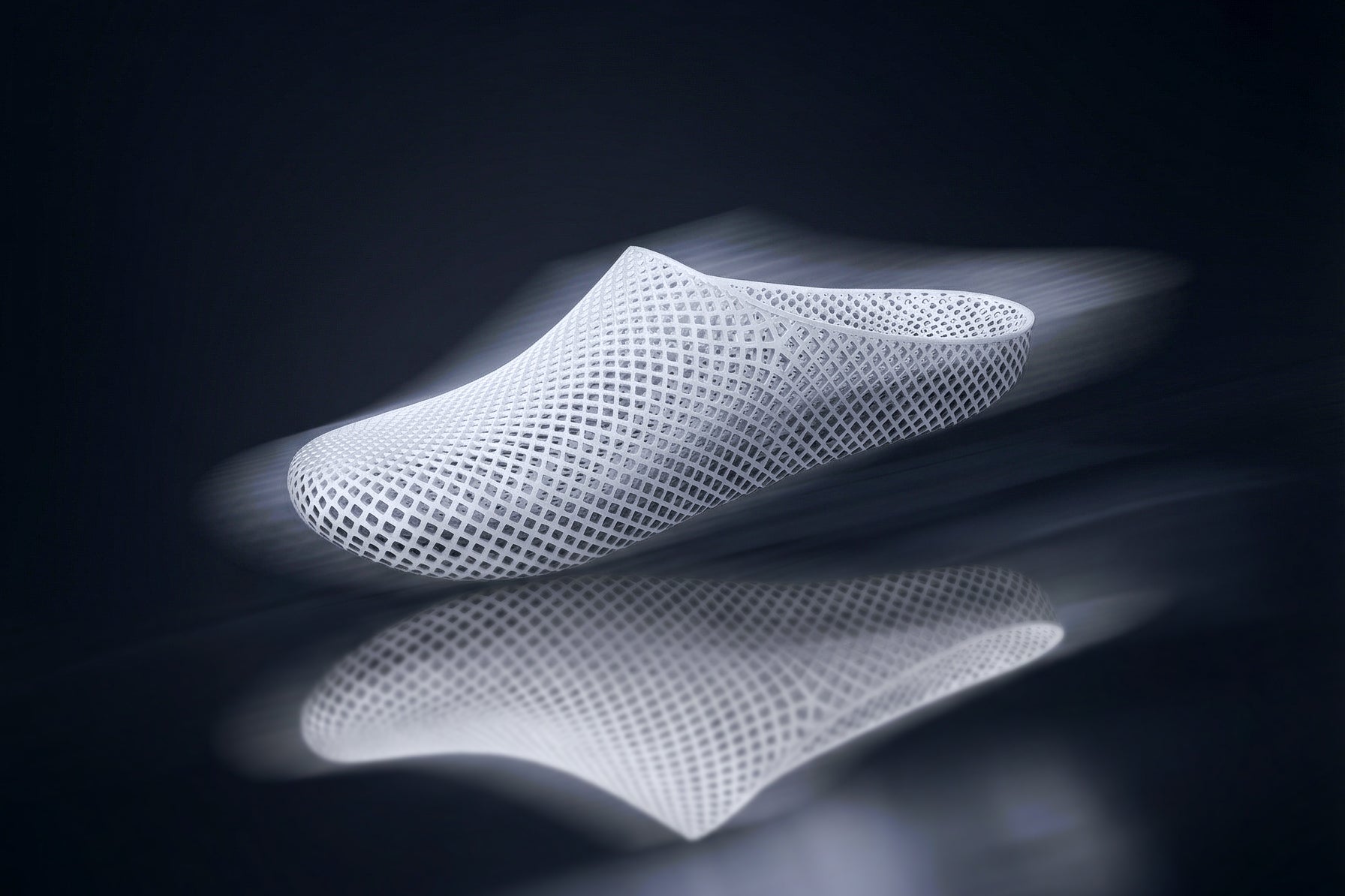

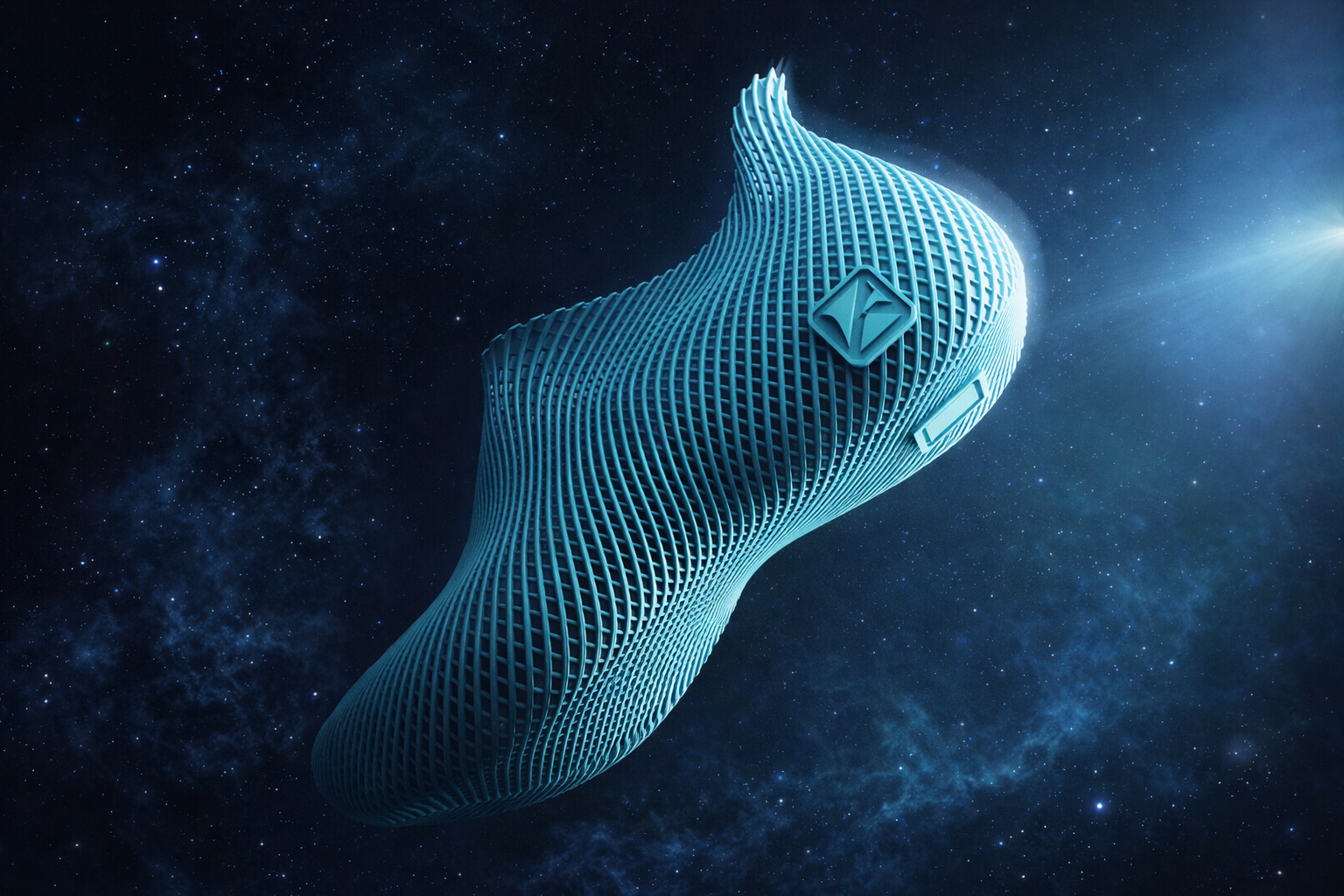

ARKKY has named its printing solution AIHALS, building on the original HALS technology by incorporating AI. This advancement increases 3D-printed shoes production speeds by 20–100 times compared to current alternative printing technologies. In terms of materials, ARKKY uses flexible composite resins with up to 53% bio-based content, prioritizing durability, fatigue resistance, long-term elasticity, and resistance to compression set, while promoting full recyclability to address common issues in early 3D-printed materials such as aging and brittleness.

Structurally, ARKKY employs AI-driven biomechanical analysis for voxel-level parameterized lattice design, dynamically adjusting density and rebound response based on foot pressure zones—delivering deep cushioning at the heel, arch support, and propulsion rebound at key stress points. The integrated lattice also creates 360° ventilation channels, achieving an optimal balance of comfort, breathability, and structural integrity.

On-Site Experience

At the expo, visitors eagerly lined up to try on ARKKY’s 3D-printed models. Real-world wearing feedback highlighted the standout performance of the unique lattice structure in load distribution and rebound response, offering a foot feel that combines softness with firm support and fast, consistent energy return. Many attendees noted that, compared to traditional foam-based midsoles, this integrated lattice design delivers clear advantages in cushioning consistency, rebound uniformity, and overall walking feedback—providing a new wearing experience that truly embodies “structure as function.”

About ARKKY

ARKKY is a technology-driven brand specializing in additive-manufactured footwear, dedicated to exploring the potential of 3D printing and advanced materials in sustainable shoe production.

Media Inquiries: media@arkky.com Official Website: www.arkky.com

Share:

Meet ARKKY on 2026 January Florida Surf Expo