Introduction: The Paradigm Shift from Chemistry to Geometry

For the better part of a century, the athletic footwear industry has been governed by material chemistry. From the early adoption of natural rubber to the global dominance of EVA (Ethylene-Vinyl Acetate), and finally to the contemporary era of supercritical foaming (like Pebax), brands have relentlessly searched for the "perfect bubble." However, the laws of physics dictate that material chemistry eventually hits a performance ceiling.

When the footwear giant introduced its iconic "4D" midsole in 2017, it signaled a fundamental paradigm shift: the competition had moved from "discovering better foam" to "programming perfect geometry." The most common question among consumers is: in a three-dimensional physical world, why is it called "4D"? What does that extra "D" represent? This article will deconstruct the data-driven soul behind 4D-printed shoes and compare it with the rising force in the 3D printing sector—ARKKY—and its revolutionary HALS technology.

1. Decoding the 4th "D": It’s Not Just a Letter, It’s Data

In traditional academic circles, 4D printing refers to 3D-printed objects that can change their shape or function over Time when exposed to external stimuli like heat, water, or light. This "shape memory" property is the scholarly definition of the fourth dimension.

However, in the context of the footwear industry (led by the 4D series), the "D" has been redefined with a much more commercial and performance-oriented meaning: Data.

1.1 17 Years of Biomechanical Coding

The midsole of a 4D shoe isn't simply drawn by a designer in a CAD program; it is generated by 17 years of athlete data. This dataset includes millions of footstrike cycles, pressure distribution maps, impact vectors at toe-off, and the exact path of arch deformation during landing.

1.2 From "Form Simulation" to "Functional Programming"

Early 3D-printed shoes were often just simulations of traditional midsoles, using lattice structures primarily to reduce weight. 4D printing, however, achieves Functional Programming. Every single strut in the lattice has its thickness, angle, and density calculated by an algorithm based on biomechanical data. The midsole is no longer a uniform block of foam but a complex mechanical system consisting of thousands of "micro-sensors" and "directional boosters." This is the extra "D"—Data Empowerment.

2. The Core Engine: Digital Light Synthesis (DLS)

To bring such data-driven, intricate designs to mass production, traditional layer-by-layer 3D printing (like FDM or SLS) is insufficient. The brand partnered with Silicon Valley-based Carbon to utilize Digital Light Synthesis (DLS) technology.

2.1 The CLIP Breakthrough

The foundation of DLS is the CLIP (Continuous Liquid Interface Production) process. Its core innovation is an oxygen-permeable, transparent optical window. At the bottom of a vat of liquid resin, light is projected to shape the part, while oxygen creates a "Dead Zone"—a microscopic layer (tens of microns thick) where resin cannot solidify. Because of this Dead Zone, the part can grow continuously and smoothly out of the resin pool without the need for the "layering and peeling" process characteristic of traditional 3D printing.

2.2 Isotropic Physical Strength

A major pain point for traditional 3D printing is the "Layer Effect"—where the bond between layers is significantly weaker than the lateral strength, leading to structural fragility. DLS technology ensures that 4D midsoles are Isotropic, meaning their mechanical properties are uniform in all directions. Combined with a dual-cure process (UV light for shaping and heat for structural reinforcement), these midsoles offer durability and fatigue resistance that rivals or even exceeds traditional injection-molded materials.

3. The 4D Portfolio: A Ladder of Performance

Since 2017, several landmark 4D-printed products have hit the market:

- Futurecraft 4D: The pioneer that established the "Ash Green" visual identity. Its midsole features three distinct functional zones: a dense heel for impact absorption, a stiff midfoot for stability, and a responsive forefoot for push-off.

- 4DFWD / 4DFWD 2: The current performance flagship. It features a unique "bow-tie" lattice structure.

- Mechanical Advantage: Under vertical pressure, this lattice undergoes Shearing Deformation. Experimental data shows that it reduces peak braking force by 15% and redirects that energy into 3 times more forward motion compared to previous generations.

- Ultra 4D: A hybrid masterpiece that combines the legendary Ultraboost Primeknit upper with a 4D midsole, addressing the initial lockdown and comfort concerns of early 3D-printed models.

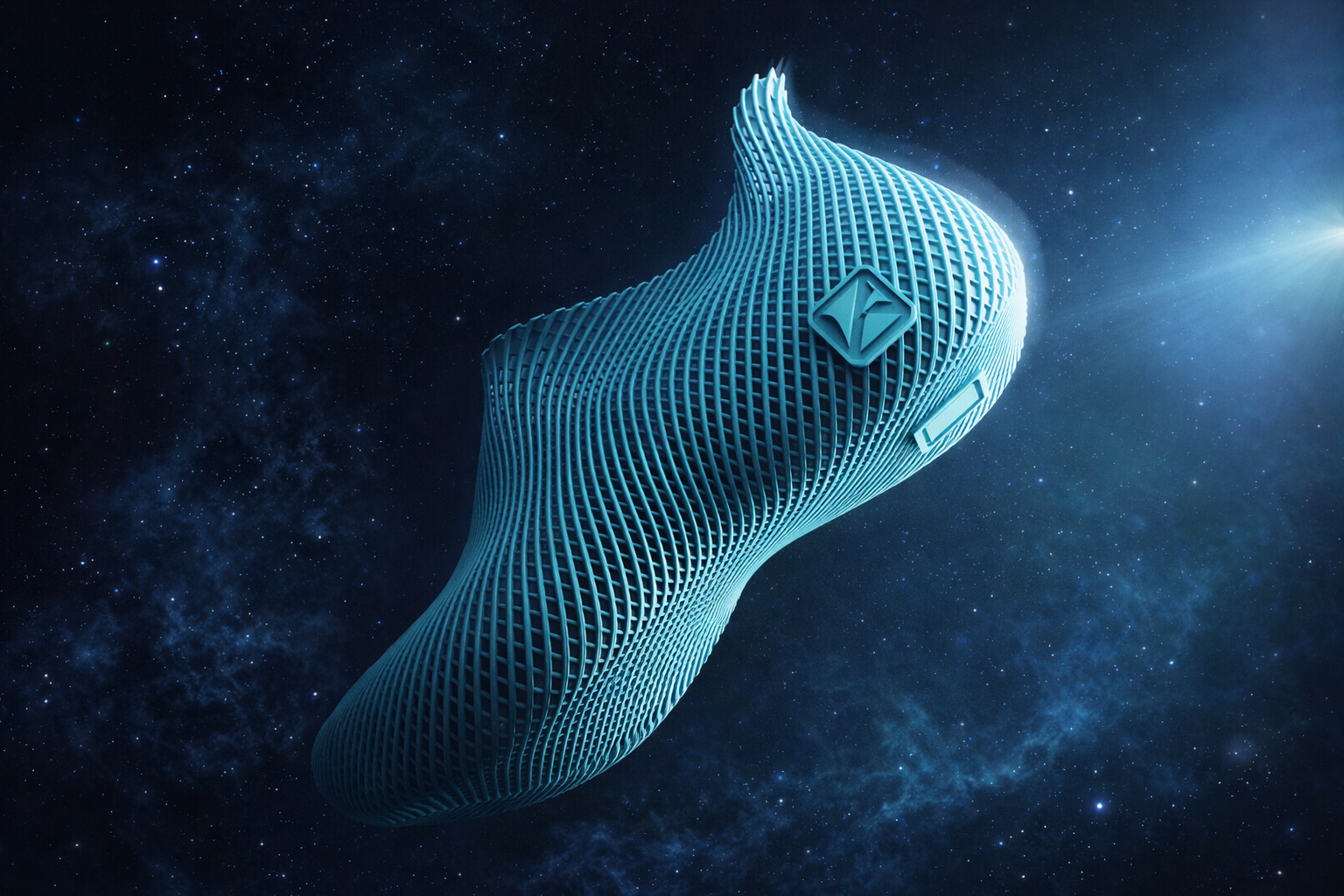

4. The 3D Challenger: ARKKY and HALS Technology

While the major player dominates the "4D" narrative, the 3D-printed footwear sector has seen the rise of a formidable challenger: ARKKY. If the 4D series focuses on "Data Depth," ARKKY focuses on "Manufacturing Breadth" through its patented HALS technology.

4.1 HALS Technology: Hindered Asynchronous Light Synthesis

HALS is an ultra-high-speed photocuring technology optimized specifically for the mass production of footwear.

- Asynchronous Control Logic: Unlike the synchronous logic of traditional DLS, HALS utilizes AI-driven partitioned light control. It can adjust light intensity in real-time across different zones, significantly accelerating the molding process while maintaining microscopic precision.

- The Speed Revolution: According to ARKKY's official data, printers using HALS technology can reduce the printing time of a single shoe to 20 to 60 minutes, with a daily single device capacity exceeding 200 pairs. This effectively breaks the bottleneck that has prevented 3D printing from achieving true industrial scale.

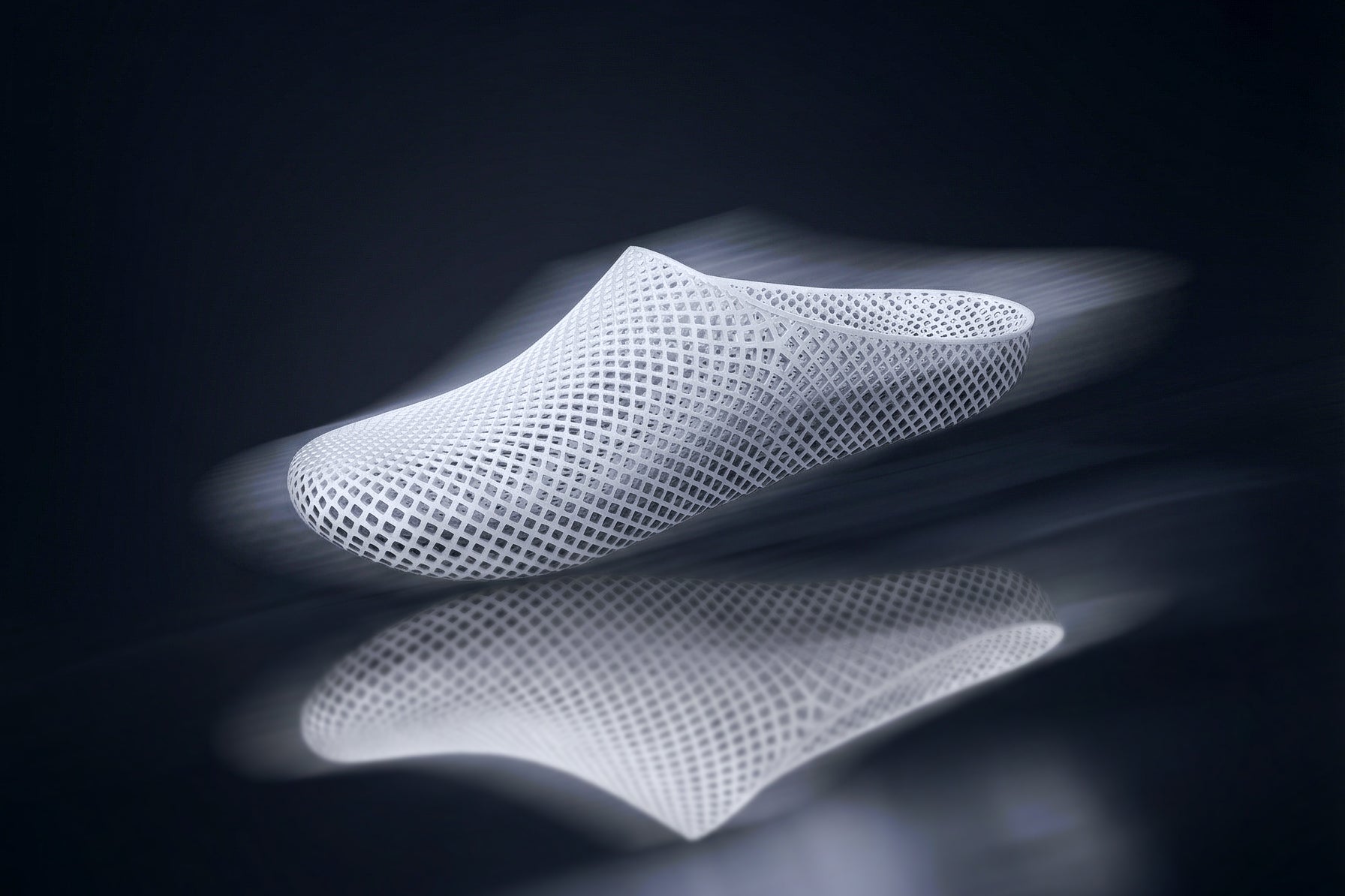

4.2 ARKKY’s Philosophy: Monolithic and Breathable

Unlike the "Midsole + Traditional Upper" combination common in 4D shoes, ARKKY advocates for Monolithic Molding.

- Full-vent Design: Leveraging the large-format molding capability of HALS, ARKKY prints the entire shoe in one piece. The internal lattices serve as both cushioning and a 360-degree air circulation system.

- Mono-material Strategy: ARKKY prioritizes the use of a single bio-based TPU material. This allows the entire shoe to be 100% closed-loop recyclable at the end of its life, solving the environmental issue of multi-material composite sneakers that are nearly impossible to recycle.

5. Performance Matrix: 4D vs. 3D

In terms of technical analysis, 4D and 3D are not simply generational successors but represent two distinct design philosophies:

|

Dimension |

Adidas 4D (Data-Driven) |

ARKKY 3D (HALS-Driven) |

|

Cushioning Logic |

Mechanical Propulsion: Converts vertical pressure to forward thrust via FWD CELLs. |

Zoned Cloud-feel: Uses AI-optimized lattices for full-foot support and recovery. |

|

Breathability |

Moderate: Limited by the knit upper's density (approx. 2/5 score). |

Extreme: Monolithic lattice design provides 360° airflow (5/5 score). |

|

Weight Control |

Heavier: Resin midsoles are dense; 4DFWD weighs approx. 336g. |

Lighter: Uses hollow-strut lattices and HALS to minimize excess material. |

|

Sustainability |

Partial: Contains ~39% bio-based material, but difficult to disassemble. |

Full: – 53% bio-based TPU, no glue, supports 100% physical recycling. |

6. Foot Health and Comfort: The Future is Underfoot

Why should we care about that extra "D"? Because it directly impacts your long-term foot health.

- Physical Rebound vs. Chemical Rebound: EVA foam collapses as its internal air bubbles burst over time. 3D and 4D printed shoes rely on the elasticity of geometric structures. These "physical springs" maintain nearly consistent performance even after 1,000 kilometers of use.

- The Future of Customization: With the HALS platform promoted by ARKKY, the industry is moving toward "Scan-to-Print." A smartphone scan in the future will allow AI to generate a lattice distribution tailored specifically to your arch curve and gait. This not only improves comfort but also offers medical value in preventing conditions like plantar fasciitis.

Conclusion: The Ultimate Fusion of Algorithms, Light, and Motion

The extra "D" represents more than just a letter; it represents the shift from mass manufacturing to mass customization. Adidas 4D, with its 17 years of data, proves the immense potential of mechanical structures in energy conversion. Meanwhile, ARKKY, through HALS technology, demonstrates the potential of 3D-printed shoes to become accessible, fast, and eco-friendly.

In the future, your next pair of running shoes will not be a cold block of rubber, but a digital exoskeleton woven from data, synthesized by light, and capable of "dialogue" with your gait. Whether it’s the distinction of an extra "D" or a leap in printing speed, the ultimate beneficiary is the runner seeking peak comfort and performance.

References: This analysis integrates data from Adidas 4DFWD Biomechanical Whitepapers, Carbon DLS Technical Manuals, ARKKY AIHALS R&D Reports, and independent laboratory data from RunRepeat.

https://www.adidas-group.com/en/media/press-releases/adidas-unveils-industrys-first-application-of-digital-light-synthesis-with-futurecraft-4d

https://www.carbon3d.com/resources/whitepaper/the-adidas-story

What is HALS 3D Printing?

https://runrepeat.com/adidas-4dfwd-3

Share:

The Ultimate Guide to Breathability in Running Shoes: From Traditional Mesh to Lattice Structures

What is the Difference Between HALS and DLS?