Why Do We Need to Distinguish Between HALS and DLS?

In the grand landscape of additive manufacturing (3D printing), footwear is undoubtedly the most representative "pioneer territory." If you've recently followed the release of midsoles with complex lattice structures from Adidas, ASICS, or Puma, you've likely encountered two terms frequently: DLS (Digital Light Synthesis) and HALS (Hindered Asynchronous Light Synthesis).

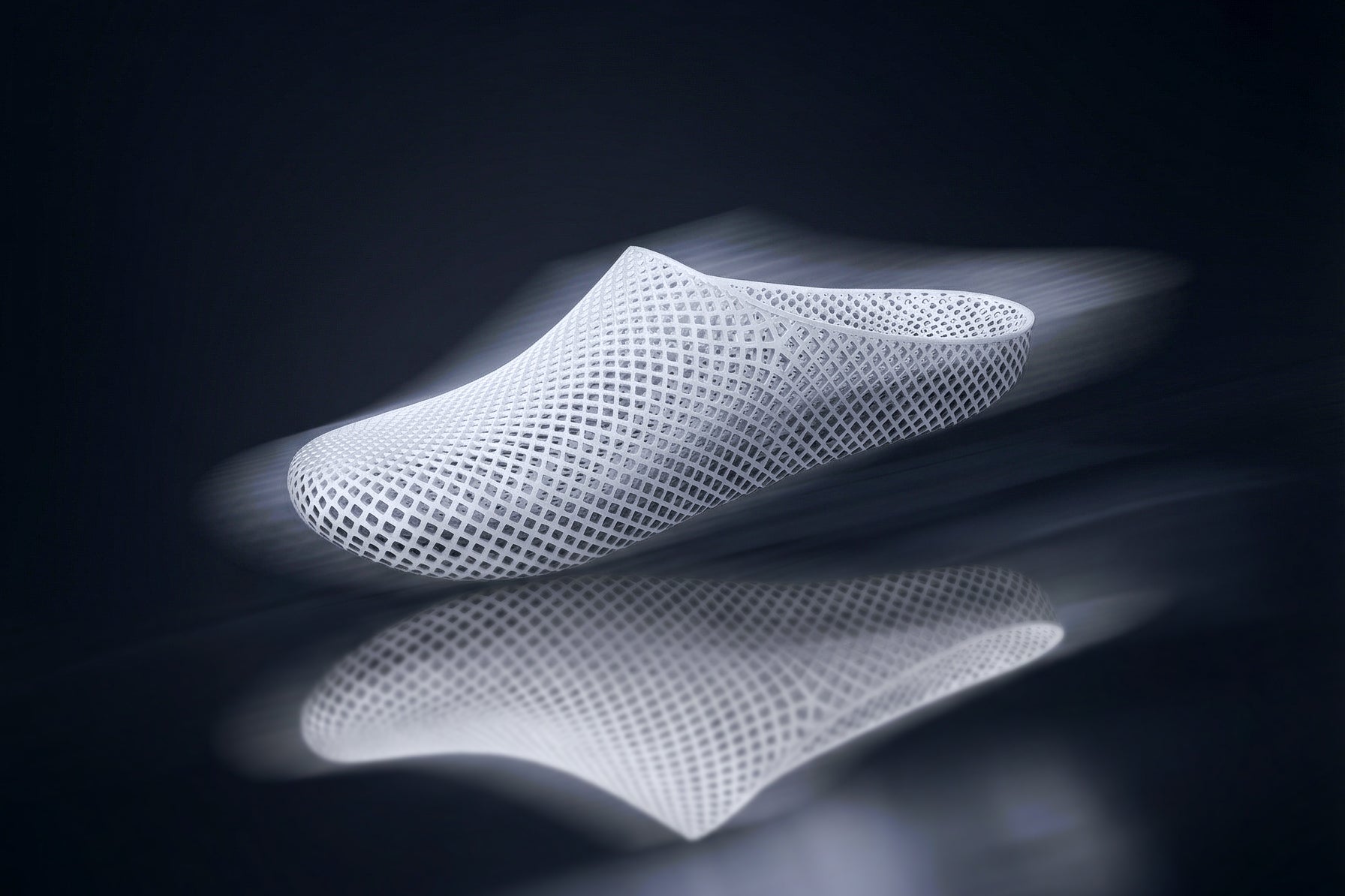

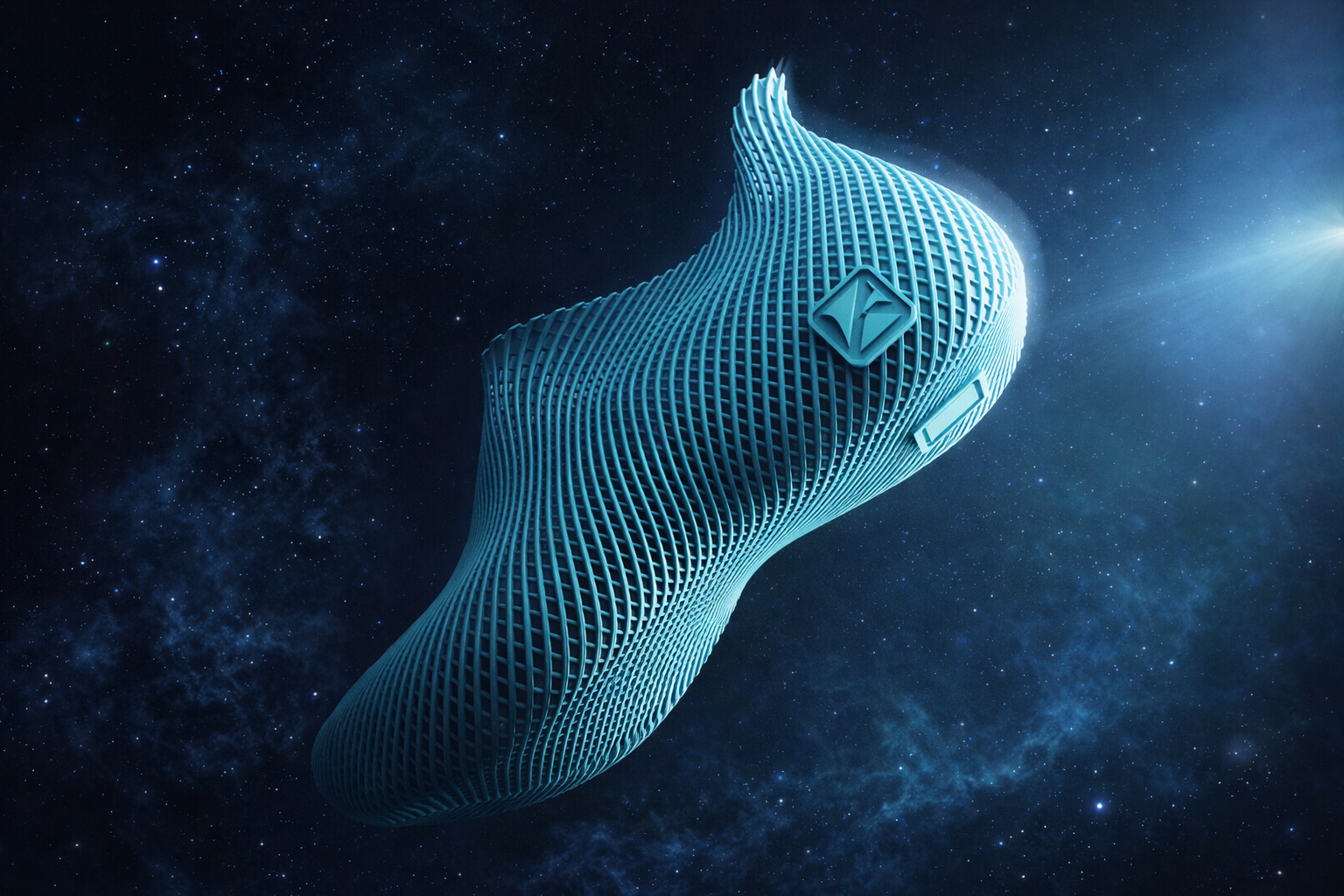

For most non-industry experts and even seasoned sneakerheads, these two terms are easily confused. The reason is simple: both fall under the broad category of "Vat Photopolymerization." Visually, both technologies use light to irradiate liquid resin, transforming it in real-time into complex elastomeric structures. In terms of output, both produce high-tech, hollowed-out lattice soles.

However, just as turbocharging and supercharging both increase engine horsepower but operate on completely different underlying logics, HALS and DLS represent two distinct evolutionary paths in 3D printing industrialization. While DLS became the industry's "fame" thanks to Adidas's successful marketing, HALS has emerged as a representative of Chinese intelligent manufacturing, launching a powerful challenge in high-speed printing and fine-tuning.

This article provides a deep technical analysis to answer five core questions about these technologies: How do their underlying principles differ essentially? Whose material system is superior? What are the limits of lattice structure control? Which has the advantage in production cost and scalability? And most importantly—as a brand or consumer, how should you choose?

Fast Definition: What are HALS and DLS?

1.1 What is DLS? The "Continuity" Revolution in Industrial Photopolymerization

DLS stands for Digital Light Synthesis, a patented technology introduced by the American 3D printing giant Carbon. In technical circles, it is more commonly known as CLIP (Continuous Liquid Interface Production).

Core Logic: Traditional photopolymerization (such as SLA or traditional DLP) is "intermittent": print one layer, lift the platform, wait for the liquid resin to re-flow and level, then print the next layer. This method is not only slow but also creates distinct physical seams (layer lines) between layers, leading to weaker mechanical properties in the Z-axis direction. The revolutionary aspect of DLS is its "Oxygen-permeable window" at the bottom. Oxygen inhibits resin curing. By introducing a trace amount of oxygen through the bottom window, DLS creates a "Dead Zone" only tens of microns thick between the liquid resin and the window. This dead zone acts like a permanent, non-drying lubrication layer, allowing the build platform to move upward continuously while the resin is cured in a constant flow.

Common Application Scenarios: The most famous application of DLS is undoubtedly Adidas's 4DFWD midsole. Additionally, it is widely used in Specialized's 3D-printed bike saddles, high-performance helmet liners, and various elastomeric structural components requiring isotropic properties (meaning identical strength across the X, Y, and Z axes). It is currently the most commercially mature and mass-production-experienced high-end 3D printing process globally.

1.2 What is HALS? The "Extreme Speed" of Asynchronous Zonal Light Control

HALS stands for Hindered Asynchronous Light Synthesis, a core technology independently developed by LuxCreo, a leading Chinese provider of 3D printing mass production solutions.

Core Logic: If DLS achieves continuity through an "oxygen barrier," HALS achieves extreme growth speed through "chemical kinetic control." HALS employs asynchronous light synthesis logic, controlling the curing time difference at the interface through specific molecular structural designs (such as inhibitor brushes). This means HALS does not rely on an oxygen dead zone but uses a more universal chemical inhibition method to reduce peeling force. Additionally, HALS introduces unique "Zonal Light Control" technology. During the printing process, the software can dynamically adjust light intensity and dose for different regions within the same projection plane. This allows it to reach speeds over 100 times faster than traditional printing while enabling micro-adjustments of softness/hardness (modulus) at different locations within the same material.

Difference from "Traditional Layer-by-Layer": Although HALS visually appears to "grow upward," it completely abandons the mechanical cycle of "layer-by-layer printing and peeling." It follows a quasi-continuous or even fully continuous manufacturing logic, significantly improving fluid dynamic replenishment efficiency. Consequently, when printing oversized parts or high-viscosity materials (such as high-performance shoe soles), it demonstrates stronger material adaptability and production speed than DLS.

2. Working Principle Comparison: How Light Transforms Resin into Structures

2.1 DLS Curing Mechanism: The Industrial Foundation of Continuity and Closed-Loop Control

The core of Digital Light Synthesis (DLS) technology lies in its revolutionary CLIP (Continuous Liquid Interface Production) process. Unlike the intermittent logic of traditional 3D printing—printing a layer, lifting the platform, and recoating—DLS creates a "Dead Zone" only tens of microns thick between the liquid resin and the optical window, thanks to an oxygen-permeable window at the bottom. Within this zone, oxygen inhibits polymerization, keeping the resin in a liquid state. This breakthrough allows the build platform to move upward continuously without interrupting the light exposure, achieving true "growth-style" printing.

Regarding the illumination mechanism, DLS utilizes a continuous projection method. The projector functions like a cinema screen, casting a seamless sequence of cross-sectional images onto the bottom of the resin vat. By eliminating mechanical pauses and recoating steps between layers, DLS-produced parts exhibit exceptional isotropic properties—meaning the strength is nearly identical across the X, Y, and Z axes. This makes their mechanical performance comparable to injection-molded parts.

To further enhance molding stability, the next generation of DLS systems (such as the Carbon M3 series) introduced sophisticated closed-loop control systems. By monitoring force and temperature in real-time during the elevation process, the system dynamically adjusts the printing speed and light intensity. This "feedback-adjustment" mechanism significantly improves repeatability in high-volume manufacturing. In midsole production, this translates to consistent hardness, weight, and rebound performance across thousands of units—a critical factor in why Adidas chose this technology for mass production.

2.2 HALS Asynchronous Light Synthesis: Evolution of Gradients via Zonal Control

While DLS pursues ultimate continuity and consistency, HALS (Hindered Asynchronous Light Synthesis) takes a path characterized by enhanced "controllability." The essence of HALS lies in its "Asynchronous" and "Zoning" control logic. It does not rely on an oxygen dead zone to maintain continuity but utilizes molecular-level inhibitor brushes and the reaction time differences of specific functional groups.

The term "Asynchronous" refers to the temporal and spatial asymmetry between the light-initiated curing speed and the interfacial adhesion speed. By precisely controlling the extent of the hindered reaction, HALS achieves fine-grained molding control without sacrificing speed. However, its most competitive technical feature is "Dynamic Zone Exposure."

In a HALS system, the print area is divided into multiple logical zones. The software can assign entirely different exposure intensities, doses, or curing times to various regions within the same cross-section. This means that even when using a single resin material, HALS can fine-tune physical properties by altering local illumination parameters. For instance, in midsole printing, the heel area can receive a higher UV dose to enhance structural stiffness, while the forefoot area is optimized for better flexibility and rebound through adjusted exposure.

This zonal light control mechanism grants HALS immense structural freedom. Traditional DLS or DLP technologies typically regulate performance by varying the thickness or density of the lattice structures. HALS, however, adds a layer of "Optical Parameter Design" on top of "Lattice Geometric Design." This dual-regulation capability allows HALS to handle complex parametric gradient designs with ease, enabling precise feedback adjustments at the millimeter or even sub-millimeter level. This provides a more fundamental and efficient technical foundation for "zonal customization based on foot feel."

3. Material System Comparison: What Materials Are Used? Where Does the Performance Differ?

Introduction: Photosensitive Resin—The "Biological Characteristic" of 3D Printed shoes

In the field of 3D printed shoes, photosensitive resin (Photopolymer Resin) plays a role similar to biological muscle tissue. Whether the technical path is DLS or HALS, the final foot feel, durability, and market performance are highly dependent on the material system. Although both technologies are based on the principle of light curing, there are significant "schools of thought" regarding their chemical formulations, curing logic, and end-performance capabilities.

Carbon, the representative of DLS technology, has established the benchmark for industrial-grade elasticity through its deep cultivation of polyurethane elastomers (EPU series). Conversely, LuxCreo, the leader in HALS technology, has launched a powerful challenge in energy return and extreme weather resistance through its EM series of high-performance single-component elastic materials. We will deeply analyze the "chemical codes" behind these two major technologies from two dimensions: differences in material requirements and key indicators for footwear applications.

3.1 Differences in Material Requirements: Formulation, Viscosity, and Curing Window

3.1.1 Viscosity: The Trade-off Between Flow and Precision

The viscosity of the material directly determines the replenishment efficiency of the liquid resin during the 3D printing process.

- Carbon DLS (EPU 41): EPU 41 is a dual-component material with relatively high viscosity. Due to its special chemical formulation designed to balance isotropic performance, its fluidity is restricted at room temperature. To meet the demands of high-speed CLIP printing, Carbon's equipment usually requires heating devices or specialized MMD (Meter, Mix, and Dispense) equipment.

- LuxCreo HALS (EM+24 / EM 1K-H): HALS technology demonstrates high tolerance in handling high-viscosity materials. For instance, the viscosity of EM 1K-H is as high as 6300 cPs at 25°C, but during the printing process, by heating the printing chamber to 40°C, its viscosity can drop to approximately 2700 cPs. This support for a wide viscosity range allows HALS to utilize prepolymers with higher molecular weights, thereby enhancing the tear strength and fatigue resistance of the final product.

3.1.2 Curing Window and Process Flow: Single-Component vs. Dual-Component

Curing logic not only affects production efficiency but also determines material stability and environmental friendliness.

- DLS Dual-Cure Path: Most Carbon DLS materials are "dual-component, dual-cure" systems. This means that after printing, the resin has only completed the first stage of UV primary curing. Subsequently, the parts must enter an oven for a second stage of thermal baking (Thermal Bake), where thermal energy triggers a secondary chemical reaction to achieve final mechanical strength. While this process ensures superior engineering performance, it is sensitive to environmental humidity, and mixed resins have a "Pot Life," after which they become waste.

- HALS Single-Component Rapid Curing: LuxCreo’s EM series tends toward a "single-component, one-stage curing" or minimalist post-processing approach. Single-component resins require no mixing, are ready to use out of the box, and excess resin can be fully recycled. For the footwear industry, which is extremely sensitive to cost in mass production, this not only significantly reduces material waste rates but also simplifies the factory post-processing workflow.

3.2 Key Indicators for Footwear Applications: Energy Return, Fatigue, and Weather Resistance

3.2.1 Energy Return: The Decider for Foot Feel

Energy return directly relates to the boost an athlete receives with every step.

- DLS (EPU 41): The material’s own Bayshore rebound is approximately 30%. Carbon's strategy is to amplify material performance through extremely complex lattice topological structures (such as gradient grids) to provide good elasticity.

- HALS (EM+24): Demonstrates a more aggressive performance in energy return. LuxCreo’s EM+24, combined with specific lattices, can reach an energy return rate of 83%, even surpassing traditional high-performance running shoe foam materials (like Pebax). This means HALS can provide a stronger propulsion feel with lighter and thinner structures, making it the preferred choice for high-end professional running shoes.

3.2.2 Compression Set: The Enemy of Midsole "Collapse"

Will the sole become flat after long-term wear? This is the core measure of material lifespan.

- DLS EPU 41: According to ASTM D395-B testing, its compression set is approximately 30%. While excellent in the 3D printing field, there will still be some loss of thickness under long-term high-intensity impact.

- HALS EM 1K-H: This material demonstrates incredible anti-collapse performance, with the compression set rate controllable within 10%. This allows the sole to maintain its initial physical form even after one million or more cyclic pressure tests, greatly extending the functional life of the sports shoe.

3.2.3 Fatigue Resistance and Weather Resistance: Surviving Cold and Heat

- Temperature Sensitivity (Glass Transition, Tg): This is where the difference is most stark. Carbon EPU 41 has a Tg of approximately -10°C. This means that in cold northern winters, the sole will noticeably harden, and elasticity will attenuate. In contrast, LuxCreo’s EM 1K-H has lowered the Tg to below -48°C. Even in extremely cold environments with temperatures reaching dozens of degrees below zero, the material remains flexible, truly achieving "all-season, all-weather" adaptation.

- Fatigue Resistance: Both perform excellently in room temperature bending tests, easily passing 50,000 or even hundreds of thousands of Ross Flex cycles. However, LuxCreo’s material system has a higher modulus retention rate after one million cycles, demonstrating stronger "marathon" attributes.

Summary: The Decision Balance of Performance Game

Through comparison, it is easy to find that the DLS material system follows a "Precision Engineering" route, ensuring high structural stability through dual-curing, suitable for the stable supply chain support of large manufacturers. Conversely, HALS represents the "Extreme Performance" route, achieving generational transcendence over traditional foam materials in rebound, weather resistance, and anti-collapse indicators.

- Choose DLS: When you need a mature solution validated by giants like Adidas, with extremely high requirements for complex structural stability.

- Choose HALS: When you pursue extreme performance data (such as ultra-high rebound), reliability in extremely cold environments, and a more environmentally friendly, efficient single-component mass production model.

4. Structural Capability Comparison: How Complex Can Lattices Be?

4.1 Structural Complexity and Zoning: Standardized Mass Production vs. Parametric Gradients

In the design language of 3D-printed midsoles, the "Lattice" is the core element replacing traditional chemical foam materials. The level of structural complexity directly determines whether a midsole can reduce weight while providing mechanical performance far exceeding that of conventional materials.

DLS Logic for Mass Production: Standardized and Robust Zoning DLS technology (represented by Carbon) emphasizes "predictability" and "industrial consistency" in structural design. Through its Carbon Design Engine software, DLS excels at dividing the midsole into discrete functional blocks (Zones). For example, the heel may be designated as a high energy-absorption zone, while the forefoot is a high energy-return zone. Within these zones, the lattice typically exhibits relatively standardized geometric features, with stiffness regulated by varying cell size or strut diameter. The strength of DLS lies in its mature "Blending Algorithm," which ensures that lattices in different functional zones achieve perfect mechanical connections at their boundaries, preventing stress concentration that could lead to fractures. This approach is ideally suited for the mass-production needs of major brands like Adidas, ensuring that every 4D midsole leaving the factory provides standard performance feedback.

HALS Logic for Freedom: Dynamic Gradients and Conformal Control In contrast, HALS (represented by LuxCreo) demonstrates a higher degree of freedom in structural design, leaning toward "Conformal" and "Continuous Gradient" models. Paired with LuxStudio software, HALS can treat the entire midsole as a continuously varying mechanical field rather than a simple patchwork of blocks. It can achieve millimeter-scale linear gradients in lattice density based on an athlete's plantar pressure heatmap. More importantly, HALS possesses the ability to handle finer and more complex topological structures. In LuxCreo's designs, one often sees non-linear, bio-inspired lattices. These structures can achieve complex non-linear compression curves with lighter weight, providing greater scope for professional competition footwear that pursues ultimate lightweight performance.

4.2 Implementation Challenges of "Density Gradients" and "Personalized Foot Feel"

Why Structural Design Defines Foot Feel More Than Material? In traditional shoemaking, foot feel is determined by the hardness (Shore C) of the foam material. However, in light-curing 3D printing, the material is usually a fixed elastomer, and 80% of the subtle tuning of foot feel depends on the structural parameters of the lattice. This is what is known as "Structured Metamaterials."

The Duality of Zonal Tuning: Geometry vs. Optical Control

- The DLS Path (Single-Dimension Regulation): In the DLS system, achieving a responsive forefoot and a stable heel primarily relies on "changing geometry." If you want the heel to be stiffer, you must thicken the lattice struts or increase their density. This creates a trade-off: enhancing support often means increasing weight.

- The HALS Path (Dual-Dimension Regulation): This is where the core competitive advantage of HALS technology lies. In addition to varying geometric structures via LuxStudio, HALS introduces unique "Zonal Exposure Control." This means that even if the lattices in two zones are identical, HALS can increase the light dose in one area during printing to achieve a higher degree of molecular cross-linking, thereby making it stiffer. This dual regulation of "Geometric Gradient + Physical Modulus Gradient" greatly reduces the difficulty of implementing complex foot feels. It allows designers to achieve subtle functional zone tuning—such as medial support reinforcement for flat feet or forefoot propulsion optimization for long-distance runners—without increasing the thickness or weight of the midsole.

Leaping Over Implementation Difficulties For DLS, the challenge lies in the calculation and simulation of massive amounts of lattice data, ensuring the connection strength of millions of struts. For HALS, the difficulty is synchronizing complex software parameters with hardware optical control capabilities in real-time. While HALS offers superior tuning freedom, it also places higher demands on the matching of design software with process parameters. In the long run, the HALS path provides a broader platform for "Bespoke" customization—using a single pressure scan, the system can customize not only the lattice distribution but even the localized softness or hardness of the material at every point. This is the ultimate form of 3D-printed footwear manufacturing.

5. Production and Scalability: Speed, Yield, Cost, and Reproducibility

5.1 Manufacturing Cycle: Print Speed and the "Bottleneck Effect" of Post-Processing

When evaluating the scalability of 3D printing, focusing solely on "print speed" is a common misconception. The true manufacturing cycle (Lead Time) must encompass every step from liquid resin to the finished midsole.

Carbon DLS: "Fast Printing, Slow Curing": DLS technology achieves staggering print speeds through the CLIP process. On a production-grade L1 printer, a complex lattice midsole typically forms in just 20 to 30 minutes. However, the real challenge for DLS lies in post-processing. Because its EPU series materials utilize a "dual-cure" system, the "green" part must be washed, supports removed, and then placed in a thermal oven for 4 to 12 hours of heat treatment. This means that while the printer is extremely productive, the slow turnover of thermal ovens requires factories to allocate vast floor space and energy for large-scale baking arrays. This follows a "batch processing" logic, ideal for brands like Adidas that produce tens of thousands of identical pairs at once.

LuxCreo HALS: "Full-Speed, Full-Cycle": HALS technology (powered by the LEAP platform) is not only comparable to DLS in print speed (reaching up to 120 cm/h) but also holds a core advantage in post-processing turnover. LuxCreo's EM series elastomers are typically single-component materials that rely primarily on high-efficiency UV secondary curing. Compared to hours of thermal baking, UV curing is usually completed within minutes to tens of minutes. This extremely short total manufacturing cycle makes HALS uniquely suited for instant customization models like "order today, deliver today." For small-batch orders requiring fast turnaround, the total output efficiency of HALS often exceeds that of DLS.

5.2 Yield and Reproducibility: The Industrial Value of Closed-Loop Control

In mass production, a 1% fluctuation in yield can translate to hundreds of thousands of dollars in losses.

The Closed-Loop Ecosystem of DLS: While Carbon’s subscription model is expensive, its core value lies in global "consistency." Because DLS machines (like the M3 or L1) feature advanced built-in force feedback and thermal closed-loop control systems, they can sense changes in resin viscosity and molding resistance in real-time and adjust automatically. This high level of digital control ensures that the same design file produces nearly identical results whether printed in Shanghai or Portland. This extreme reproducibility is the foundation that allows DLS to support global distributed manufacturing.

The Low Peel Force Guarantee of HALS: LuxCreo HALS technology significantly reduces peel force during the printing process through its patented "Hindered Asynchronous" logic. In 3D printing, peel force is the primary cause of part deformation and support failure. HALS claims a print success rate as high as 99%, which is critical when processing structurally complex, oversized midsoles (such as on the Lux 3L platform printing multiple units at once). Although HALS started slightly later than Carbon in terms of global cloud-based device management, its physical-level stability provides an excellent yield guarantee for localized "Smart Micro-Factories."

5.3 Cost Structure: Fixed Investment vs. Variable Waste

Differences in Equipment Investment Models:

- Carbon DLS (Subscription Model): Carbon employs a "lease-only" subscription model. The annual subscription fee for an L1 printer is approximately $250,000. This model transforms large capital asset purchases into annual Operating Expenses (OPEX). For large brands with abundant cash flow, this includes continuous software updates and rapid after-sales support. However, for small-to-medium startups, the high fixed subscription fee represents a significant barrier to entry.

- LuxCreo HALS (Purchase/Flexible Model): LuxCreo typically offers more flexible equipment purchase or leasing options. Its initial entry cost is generally lower than Carbon's long-term subscription fees. This makes HALS the preferred choice for many companies seeking "flexible supply chains" and medium-scale mass production.

Material Waste and Environmental Costs:

- DLS Challenges: Since materials like EPU 41 are dual-component (Part A + B), they require expensive MMD (Meter-Mix-Dispense) equipment. Once the resin is mixed, it has a fixed "Pot Life." If a print failure causes an interruption, the mixed resin often becomes waste, leading to significant cost loss.

- HALS Advantages: LuxCreo’s EM series are mostly single-component materials requiring no mixing. More importantly, HALS systems have an extremely high material recovery rate. Excess resin can be filtered and returned directly for reuse, which not only significantly reduces material costs (by approximately 20%~30%) but also aligns better with the ESG (Environmental, Social, and Governance) goals pursued by modern footwear brands.

5.4 Conclusion: Mass Production or Customization?

DLS is Best For: Large global brands (such as Adidas, Specialized). When you need to produce a few fixed "hit models" for millions of potential users, the mature global supply chain and exceptional part stability of DLS are irreplaceable. Despite high unit costs, the level of automation at scale is extremely high.

HALS is Best For: Companies pursuing "Extreme Agility" and "High Customization" (such as personalized projects by ASICS or Puma). The rapid full-cycle turnaround, low material waste, and more flexible investment model of HALS give it stronger vitality in the small-batch, multi-batch customization market (Mass Customization) and regional manufacturing centers.

6. Application Comparison: Why Are HALS and DLS Frequently Compared in Footwear?

6.1 Typical Advantages of DLS in Midsoles: Maturity, Stable Mass Production, and Structural Consistency

In the decade-long journey of additive manufacturing (3D printing) entering the footwear industry, Digital Light Synthesis (DLS) has undoubtedly been the "pioneer" and "industry cornerstone." Since Adidas released the first Futurecraft 4D in 2017, DLS technology has been tightly coupled with high-performance midsoles.

Ultimate Industrial Maturity: The greatest advantage of DLS lies in its complete industrialized ecosystem. Carbon provides not just printers but a closed-loop system encompassing "automated lattice design software (Design Engine) + validated elastomers (EPU series) + cloud-based intelligent control." For footwear brands, this means extremely low R&D risk. Choosing DLS means selecting a mature solution validated by millions of commercialized products. This "certainty" is paramount for giant brands (such as Adidas and Specialized) that need to support large-scale global launches.

Global Performance Consistency: Shoemaking is a globally produced industry. Relying on its powerful cloud-based closed-loop control, DLS ensures the true realization of "Digital Twins." Whether in an OEM factory in Asia or a smart factory in North America, as long as the same slicing file and Carbon-certified resin are used, the resulting midsoles remain nearly identical in mechanical properties, rebound feel, and geometric precision. This high degree of reproducibility eliminates batch differences caused by cross-regional production, allowing brands to confidently promote the same 3D-printed footwear globally without worrying about discrepancies in foot feel from different origins.

Structural Stability and Durability: The dual-cure process of DLS (primary curing + subsequent thermal baking) grants midsoles exceptional engineering stability. After heat treatment, the molecular chains in materials like EPU 41 form an extremely robust cross-linked network. In practical use, this means DLS midsoles exhibit excellent tear resistance and anti-collapse properties, capable of withstanding long-term, high-intensity athletic wear. This is why DLS remains the premier choice in sectors demanding "flagship-level durability" and "industrial-grade standards."

6.2 Potential Advantages of HALS in Midsoles: Lightweight Limits and Fine Gradient Tuning

While DLS is the mature industrial benchmark, HALS (Hindered Asynchronous Light Synthesis) is the "performance geek" with immense potential. LuxCreo is breaking the physical boundaries of 3D-printed soles through deep synergy between software and hardware.

Enhanced Structural Parameterization and Lightweighting: HALS technology, paired with LuxStudio software, can handle micro-topological structures even more complex than those of DLS. In high-performance running, every gram saved is crucial. HALS can achieve finer strut diameters and more conformal mesh distributions, meaning it provides the same support with less weight. Furthermore, LuxCreo is pioneering "outsole-free" designs—using highly wear-resistant, high-elasticity EM materials to print soles with integrated traction patterns, eliminating the weight of traditional rubber outsoles. This "integrated shoemaking" concept makes HALS highly attractive for professional competition shoes pursuing ultimate lightweighting.

Dual Gradient Tuning of "Geometry + Material": This is the "killer feature" that distinguishes HALS from DLS. As mentioned earlier, HALS’s "zonal light control" capability allows for differentiated material properties across various positions on the same sole. While traditional DLS can only tune stiffness by changing lattice density, HALS can make the material stiffer at high-load points through optical control without altering the geometric structure. This dual-dimensional regulation makes performance distribution (such as dynamic rebound gradients) extremely delicate, enabling a silk-smooth transition in foot feel from heel to forefoot. This is revolutionary for top athletes with discerning foot-feel requirements or rehabilitation footwear needing precise functional zoning.

Ultra-Fast Iteration and Instant Customization: Thanks to HALS’s high-speed printing (LEAP platform) and simplified post-processing that eliminates long thermal baking, the R&D cycle is exceptionally short. It may take less than two hours from a designer modifying a parameter to receiving a physical sample for wear-testing. This high efficiency not only accelerates product iteration for brands but also makes "in-store instant customization" possible. The collaboration between ASICS and LuxCreo is based precisely on this rapid response capability, enabling personalized footwear delivery for specific users.

6.3 Selection Recommendations: Deciding by Brand Goals and Product Positioning

Based on different brand stages and product goals, here is a selection guide grounded in HALS and DLS characteristics:

Scenario 1: Pursuing "Mass Production Stability" and "Global Distribution"

- Recommended Path: Favor DLS

- Reason: If your goal is to promote 3D-printed soles to global retail channels like Adidas, the supply chain maturity, standardized material properties, and exceptional batch consistency of DLS are core guarantees. Although subscription fees and material unit prices are higher, it saves significant supply chain management costs and quality risks.

Scenario 2: Pursuing "Extreme Performance" and "Structural Innovation"

- Recommended Path: Favor HALS

- Reason: If you are developing a record-breaking professional competition shoe or need highly precise functional zoning (such as orthotic shoes for specific injuries), HALS’s dual-dimensional gradient control and lighter mesh designs provide broader tuning possibilities. Its integrated printing capability also helps subtract unnecessary rubber outsole weight.

Scenario 3: Pursuing "Agility" and "Personalized Customization"

- Recommended Path: Tend Toward HALS

- Reason: The high-speed printing and simplified post-processing of HALS give it an overwhelming efficiency advantage in small-batch production and bespoke customization. If your business model involves in-store scanning and on-site printing, or requires high-frequency limited-edition iterations for vertical communities, HALS’s lower barrier to entry (non-subscription) and high turnover rate are more ideal.

Scenario 4: Startups and Scientific Research

- Recommended Path: Comprehensive Evaluation of HALS

- Reason: HALS typically offers more flexible equipment investment, and its single-component materials are recyclable. For startups or research institutions needing to control upfront investment and experimental costs, it offers better cost-effectiveness. Furthermore, its openness (compared to Carbon’s closed ecosystem) is generally more conducive to deep collaborative R&D at the material and process levels.

7. Clarification of Common Misconceptions (FAQ)

7.1 "Is HALS an Upgraded Version of DLS?"

In the rapid evolution of additive manufacturing (3D printing), the market often tends to understand technology through "version numbers," assuming that HALS (Hindered Asynchronous Light Synthesis), which appeared later, must be the 2.0 version of DLS (Digital Light Synthesis). This is a typical cognitive misconception.

Parallel Technical Routes Without Intersections In essence, DLS and HALS are two entirely different parallel solutions to the same core physical challenge—"Peel Force." In light-curing printing, liquid resin adheres to the transparent window at the bottom as it solidifies. Achieving "uninterrupted continuous printing" is the key to breaking speed limits:

- DLS (Carbon): Employs a "Chemical Barrier Method." By permeating oxygen through an oxygen-permeable membrane at the bottom, it utilizes oxygen's ability to inhibit free-radical polymerization to create a "Dead Zone" of several tens of microns. Within this dead zone, the resin remains liquid, enabling continuous growth.

- HALS (LuxCreo): Employs a "Kinetic Hindrance Method." It does not rely on oxygen but instead controls the timing of curing at the molecular level through specific molecular structural designs (such as inhibitor brushes) and asynchronous photochemical reaction logic.

Conclusion: HALS is not an improvement built upon DLS but a completely independent underlying technical path. The two differ fundamentally in patent landscapes, equipment architecture, and software algorithms. One can compare them to "turbocharging" versus "supercharging"—both enhance engine power but operate on distinct principles. They are parallel technologies rather than sequential replacements; choosing between them depends more on application scenarios, such as material compatibility and production flexibility.

7.2 "Does '4D' Necessarily Mean HALS?"

The term "4D" is highly misleading in the footwear market, largely due to Adidas's successful marketing.

Brand Marketing vs. Technical Terminology When Adidas released "Futurecraft 4D," the "4D" actually represented the fourth dimension of performance generated by "Digital Data," and the technology used behind it was Carbon's DLS. Therefore, historically speaking, 4D was initially deeply tied to DLS.

The True Concept of 4D Printing In scientific definitions, "4D printing" refers to 3D-printed objects that can change their shape or properties over time when exposed to external stimuli (such as temperature, humidity, or light).

- HALS and 4D: LuxCreo is frequently associated with 4D because it developed materials with "shape memory" characteristics (such as 4D clear aligners), which can undergo precise morphological changes in the oral environment. However, in midsole applications, the so-called "4D midsole" refers more to data-driven lattice structure design rather than time-dependent deformation.

Misconception Clarification: HALS is simply an efficient printing method for achieving 3D/4D structures; it is not synonymous with "4D midsoles." You can print 4D soles using DLS, and you can also print them using HALS. In the sneaker world, "4D" is more of a design label for "parametric design" and "data-driven foot feel" rather than a name for a specific printing process.

7.3 "Are Light-Cured Resin Shoes Necessarily Fragile?"

The early impression of light-cured 3D printing was that it was "fragile," "prone to yellowing," or "only for display, not for wear." These conclusions were based on traditional prototyping resins. Modern industrial-grade resin midsoles have undergone a qualitative transformation in performance.

Durability Depends on More Than Just "Light Curing" Vat photopolymerization (light curing) is merely a molding method. The durability of a sole is determined by a "Trinity":

- Chemistry (Formulation): Modern 3D-printed soles primarily use polyurethane (PU) elastomers. By adjusting molecular chain segments, researchers can achieve elongation rates of up to 1000% and exceptional rebound. Modern resins can withstand "over 1 million dynamic flex cycles" without cracking.

- Architecture (Structure): Lattice design is not just for elasticity; it is also for stress distribution. Excellent lattice design prevents localized stress concentration, thereby thwarting fatigue fractures.

- Post-Processing: The dual-cure thermal baking of DLS significantly enhances chemical cross-linking and eliminates residual monomers. Similarly, HALS’s precise UV post-curing ensures the full release of material performance.

The Truth About Environmental Resistance Many worry that resin soles will become brittle under sunlight (UV radiation). In fact, high-end 3D-printed footwear materials (such as LuxCreo's EM series or Carbon's EPU series) incorporate highly efficient light stabilizers and antioxidants into their formulations. Current 3D-printed midsoles have comprehensively surpassed traditional EVA and even some ETPU foam materials in terms of resistance to yellowing, hydrolysis, and maintaining elasticity in low-temperature environments (withstanding temperatures below -40°C).

Conclusion: If a pair of 3D-printed shoes is not durable, it is a flaw in that specific product's "formulation, structure, or post-processing," not an inherent defect of "light-curing technology" itself. Modern high-performance light-cured elastomers possess the industrial-grade lifespan required for mass-produced athletic soles.

8. Conclusion: Summary of Differences + Reader’s Selection Guide

8.1 Core Differences: 5 Key Takeaways

After an in-depth exploration of principles, materials, structures, and production models, we can summarize the core differences between HALS and DLS across five key dimensions:

- Molding Logic: Chemical Barrier vs. Kinetic Control DLS relies on a physical "Oxygen Dead Zone" to achieve continuous liquid interface production, ensuring industrial-grade consistency and isotropy. HALS, conversely, achieves continuous growth through chemical-level "Hindered Asynchronous Reaction," freeing it from oxygen dependency and offering superior boundary stability.

- Tuning Dimensions: Geometric Gradient vs. Dual Geometric + Physical Gradient DLS primarily regulates foot feel by varying the thickness and density of lattice structures (Single-Dimension Geometric Regulation). HALS builds upon geometric regulation by introducing "Zonal Optical Control" parameters, allowing direct adjustment of local molecular cross-linking density through varied light doses (Dual-Dimension Physical + Geometric Regulation).

- Material System: Dual-Component Thermal Cure vs. Single-Component Light Cure DLS utilizes ultra-stable dual-component resins that require hours of thermal baking, making it suitable for the stable global supply chains of major brands. HALS employs single-component resins with rapid post-processing and fully recyclable excess material, balancing high performance with extreme production efficiency and environmental sustainability.

- Post-Processing & Cycle Time: Long-Term Heat Treatment vs. Rapid UV Turnover The thermal curing stage of DLS acts as a production bottleneck, making it ideal for pre-planned mass production. The rapid UV curing of HALS drastically shortens total manufacturing cycle time, making it the preferred choice for "Instant Customization" and "Agile Response" supply chains.

- Core Value: Mature Industrial Standards vs. Extreme Customization Freedom DLS represents the most mature industrialized solution for 3D-printed soles, serving as the benchmark for mass production. HALS represents the upper limit of performance tuning and the flexibility of personalized customization.

8.2 Reader’s Selection Guide: Which 3D Printed Shoe is Right for You?

When you stand before a shelf (or webpage) featuring running shoes labeled "3D Printed" or "4D Midsole," understanding the underlying technology helps you make a more informed choice.

1. Selection Based on Usage Scenario

- Long-Distance Running / Professional Marathons: Choose HALS-based Products If you seek extremely high energy return (rebound) and performance stability over long distances, the EM series materials used in HALS, combined with dual-dimensional gradient tuning, provide a more refined propulsive feel. Products using LuxCreo technology often feature energy return rates exceeding 80%, effectively reducing muscle fatigue during long runs.

- Gym / General Training: Choose DLS-based Products Training shoes require excellent lateral support and multi-directional stability. The isotropic characteristics of DLS (such as Adidas 4DFWD) are outstanding, providing very robust feedback under lateral movements and heavy-load support, ensuring consistent foot feel in all directions.

- Daily Commuting / Lifestyle: Both, with a Focus on DLS Design DLS products (like the Adidas 4D series) have a more mature supply chain, offering greater variety in colorways and upper designs. Their classic, regular grids are highly recognizable. For daily walking, the resilience of DLS provides a premium feel, supported by robust brand warranties.

2. Selection Based on Weight and Preference

- Heavyweight Runners (Over 85kg): Recommended HALS Bespoke Heavyweight users' greatest concern is "bottoming out" the midsole or long-term collapse. HALS’s EM 1K-H series materials, with extremely low compression set (<10%) and localized reinforcement achieved via light control, provide more durable support for high-impact points, preventing the sole from losing elasticity prematurely.

- Seeking Balanced "Cloud-Like" Softness & Bounce: Recommended High-End DLS Models DLS excels at using complex geometric lattice topologies to create a unique linear energy-absorption feedback. If you prefer a feel that transitions from soft to resilient with extremely uniform feedback, the mature DLS lattices, validated by millions of simulations, offer highly predictable comfort.

- Users in Extremely Cold Regions: Must Choose HALS Series If you wear these in cold winters, verify the material. Carbon EPU 41 hardens significantly below -10°C. In contrast, LuxCreo’s EM series resins have a Tg as low as -48°C, maintaining "soft bounce" even in icy conditions—the only technical guarantee for all-season wear.

3. Quick Decision Matrix

|

Your Requirement |

Recommended Path |

Core Reason |

|

Extreme Rebound / Pursuing PB |

HALS (e.g., LuxCreo High-end) |

Higher material return rate + Precise zonal tuning |

|

Standardized / Proven Stability |

DLS (e.g., Adidas 4D, Specialized) |

Industrial consistency, global standards, proven durability |

|

Polar / Cold Environment Use |

HALS |

Excellent low-temperature physical properties (Tg as low as -48°C) |

|

Bespoke Customization (Arch Support) |

HALS |

Dual Geometric + Optical tuning for precise pressure matching |

|

High-Intensity Training / Lateral Support |

DLS |

Superior isotropic mechanical properties and structural integrity |

Final Thoughts: Technology at the Service of Your Feet

Whether it is the robust industrial aesthetics of DLS or the fine-grained performance regulation of HALS, the advent of 3D printing is moving footwear manufacturing from the era of "mass foaming" into the era of "digital metamaterials." For readers, the goal isn't to fret over which technology is "more advanced" but to find the set of "digital codes" that best matches your gait, weight, and environment. In the future, you won't just be picking a size in a store; algorithms and beams of light in a lab will precisely customize that one centimeter of comfort just for you, based on your data.

Share:

Why 4D-Printed Shoes Have One More “D” Than 3D