At the intersection of technology and fashion, a "footwear revolution" is quietly unfolding. Recently, ARKKY, a world-leading innovative footwear brand, officially announced the release of its next-generation 3D-printed shoes. This represents not only a technological upgrade for the ARKKY brand but also a significant milestone for the entire footwear industry as it transitions from traditional analog manufacturing to fully digital production. By introducing Hindered Asynchronous Light Synthesis (HALS) technology and brand-new bio-based materials, ARKKY aims to shatter the "expensive and niche" stereotype of 3D-printed shoes and propel them into the global mass market.

Technological Core: HALS Ultra-High-Speed Printing

At the heart of ARKKY's new generation of 3D-printed shoes lies its proprietary HALS (Hindered Asynchronous Light Synthesis) technology. Traditional 3D-printed shoe production often faces bottlenecks such as low efficiency and high costs. HALS technology achieves ultra-high-speed continuous printing by optimizing fluid dynamics and thermal control during the light-curing process. Compared to the industry average, HALS technology increases production speed several times over, with a daily capacity of more than 200 pairs per machine. This breakthrough significantly reduces production costs, clearing the efficiency barriers for the mass adoption of 3D-printed footwear.

Material Innovation: 53% Bio-Based Composite

ARKKY has taken a forward-looking step in balancing environmental sustainability with performance. The new series utilizes a newly developed high-molecular flexible composite material with a bio-based content of up to 53%. This material not only offers exceptional durability and fatigue resistance—addressing the pain points of early 3D printing materials such as aging and brittleness—but is also 100% recyclable. Its superior elastic recovery (long-lasting elasticity) ensures that the shoes maintain their original feel even after millions of compressions.

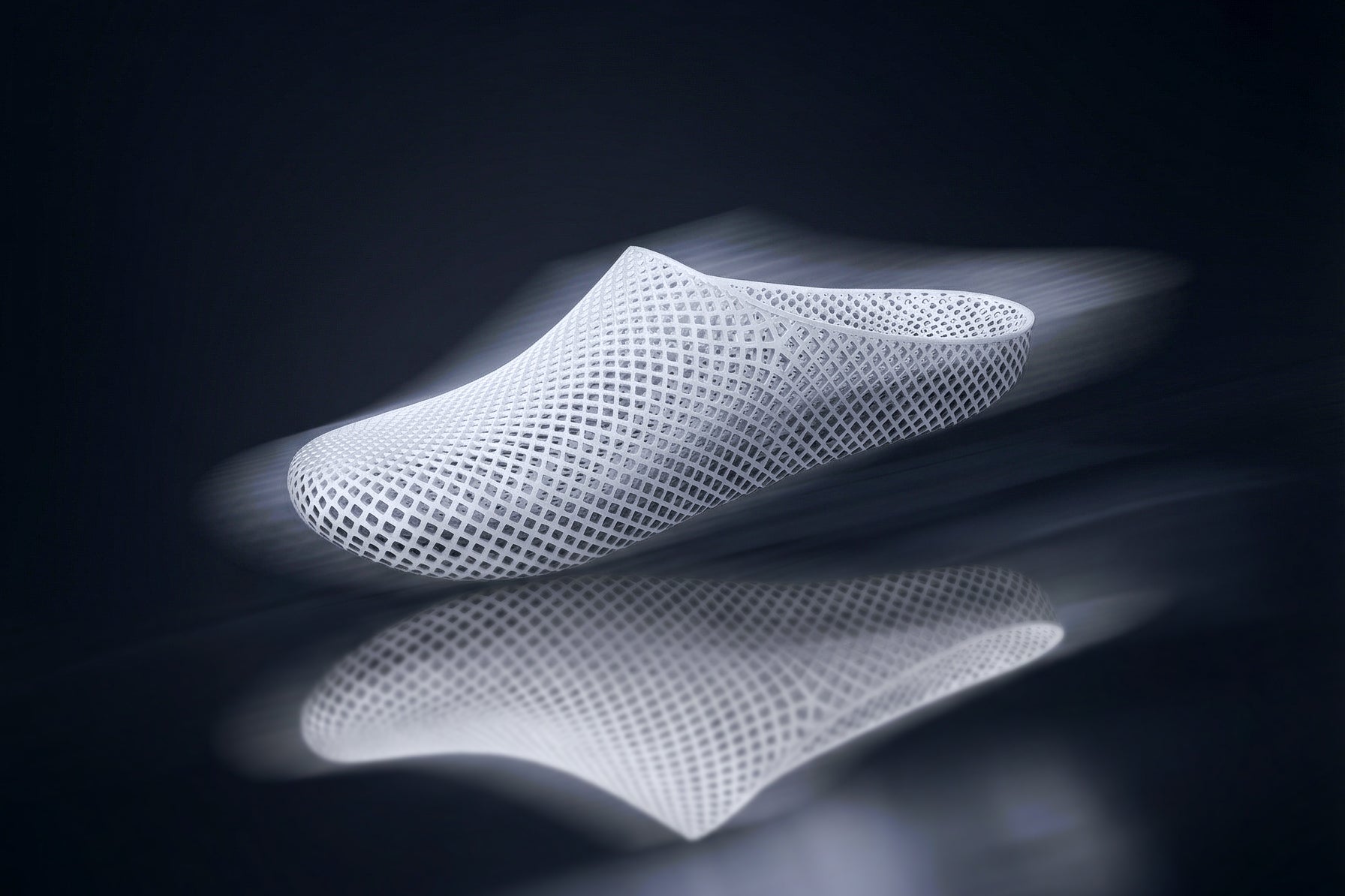

Peak Comfort: AI-Driven Lattice Structures & Voxel-Level Control

Comfort is the soul of ARKKY's design. Utilizing an AI-driven biomechanical analysis system, ARKKY has implemented "Voxel-level" parametric design for the soles. Unlike traditional sneakers with a single-density midsole, ARKKY’s 3D-printed lattice structures can dynamically adjust their density and shape based on the pressure distribution of different foot areas. It provides deep cushioning at the heel, firm support at the arch, and high-rebound power response at core pressure points. Simultaneously, this integrated lattice design allows for 360° all-around breathability, completely solving the stuffiness issue found in traditional sealed soles.

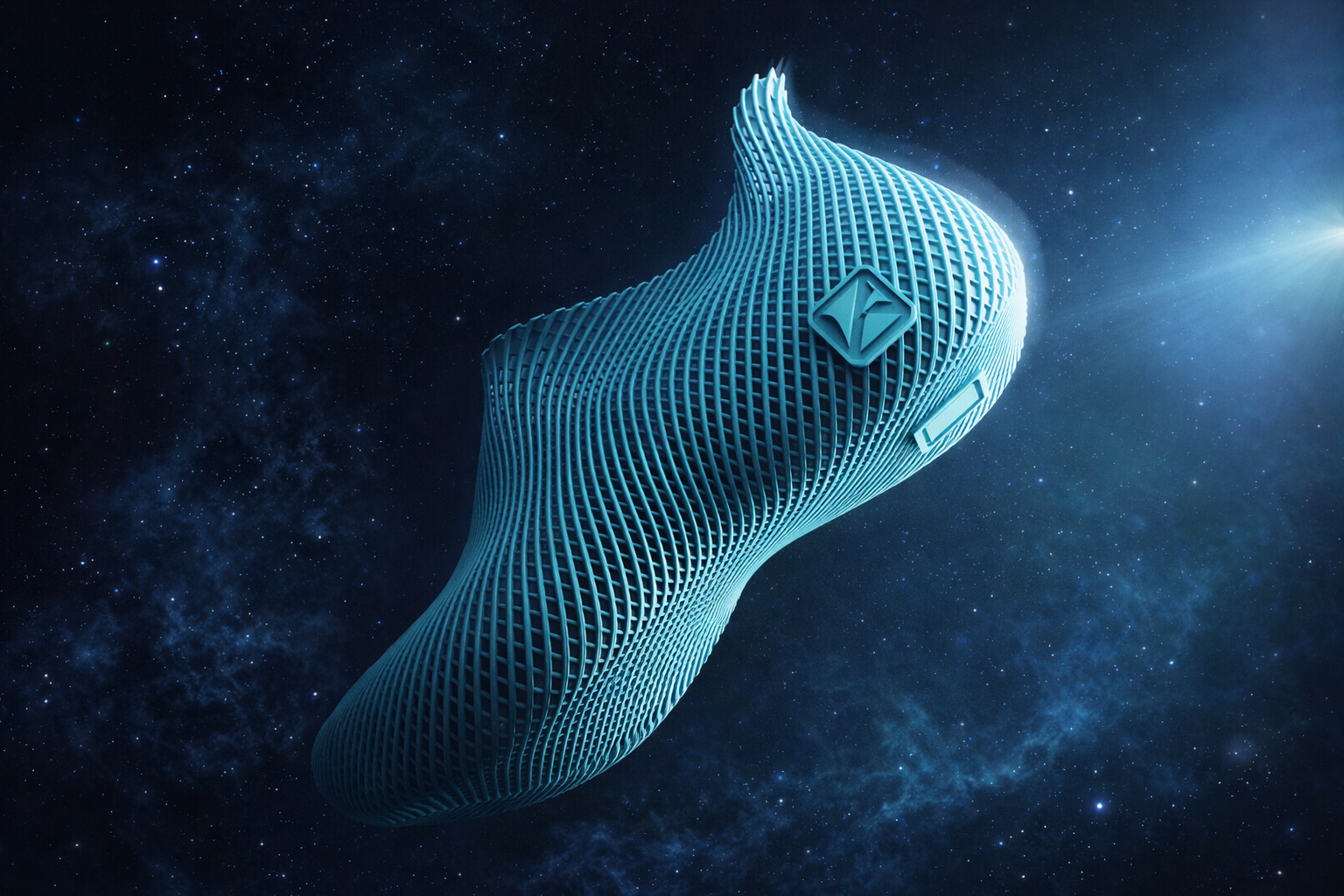

Design Aesthetics: Seamless Fusion of Tech and Daily Life

ARKKY believes that technology should not be a cold laboratory product but should serve daily life. The next-generation products blend minimalism with a futuristic aesthetic. The natural rhythm of the lattice structure is not only a functional manifestation but has also become a unique visual signature. Whether it is the "Daily Ease" series designed for daily commuting or the "Sport Form" series (exemplified by the Aerodash) focused on performance, both showcase ARKKY’s excellent aesthetic tone, making them easily adaptable to business, sports, and casual scenarios.

"We are not just making shoes; we are reshaping the way humans connect with the ground," said the CEO of ARKKY. "Through our next generation of 3D printing technology, we want every consumer to enjoy the precision, comfort, and sustainability brought by digital manufacturing."

Share:

ARKKY Redefines Comfort with the 3D Printed CozLite 101 Sandal