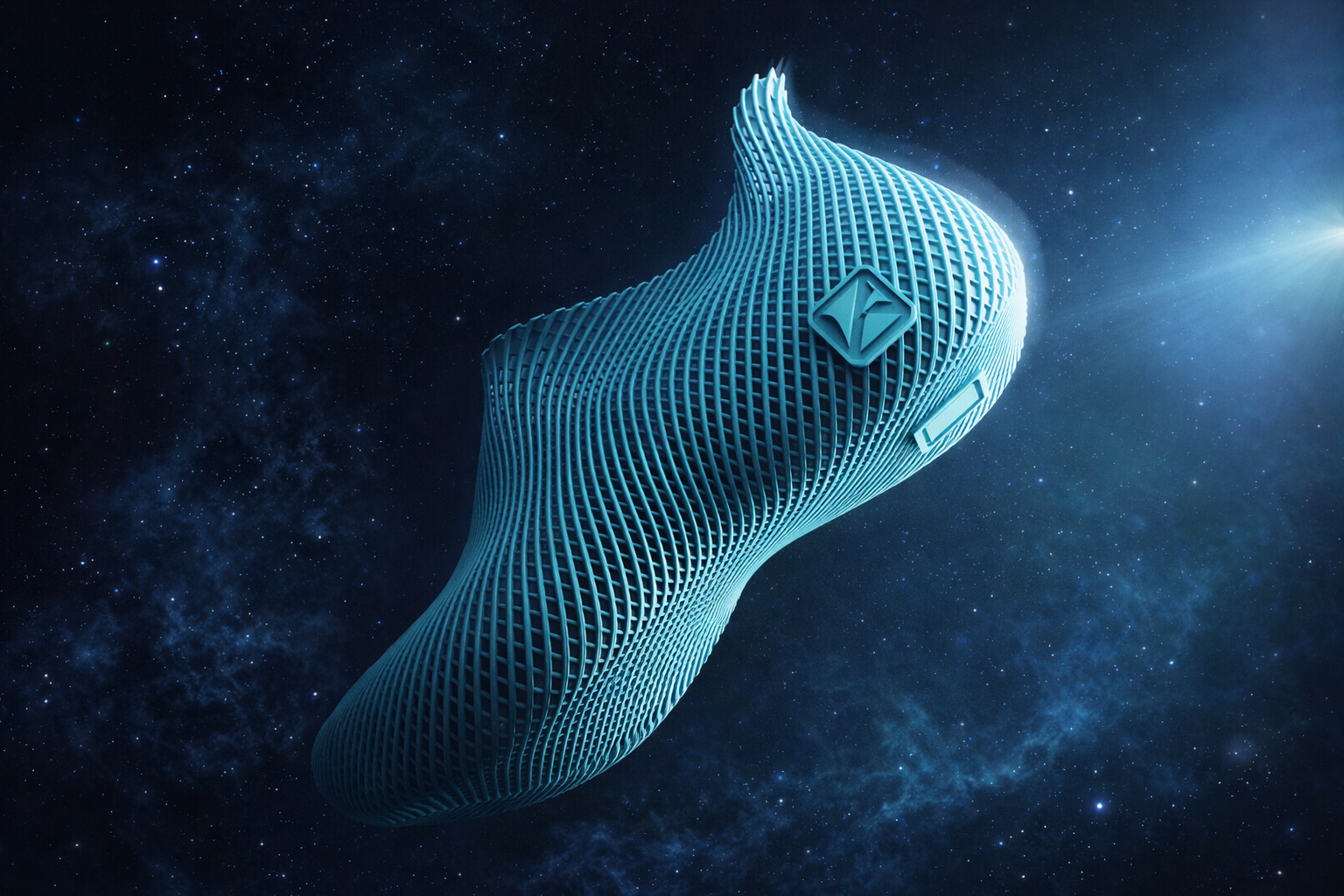

[AZ, USA] — Innovative footwear brand ARKKY today announced its self-developed AI-HALS (AI Hindered Asynchronous Light Synthesis) technology. This breakthrough technology combine artificial intelligence algorithm with high speed light curing process, making the production efficiency of 3D printed shoes increase 20-100X, and bring an unprecedented speed revolution for the footwear industry.

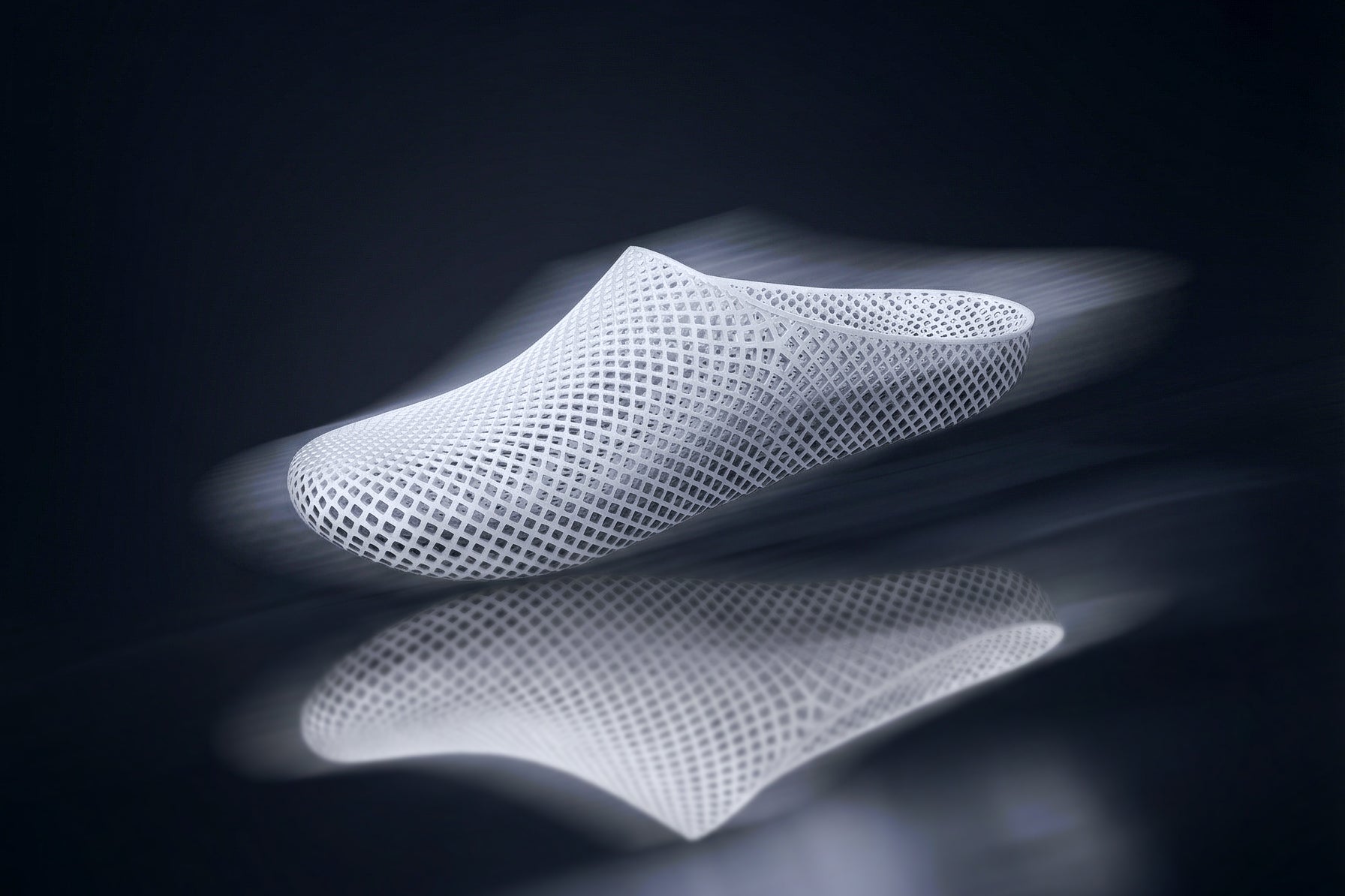

In the traditional 3D printing shoemaking process, although product has advantage in design freedom, breathability, comfort and personalization, the printing speed is always the key bottleneck for large scale use. ARKKY’s AI-HALS technology introduce intelligent algorithm to optimize lattice structure in real-time, and at same time use high-speed array light source for large area curing, realizing outsole and upper integrated fast forming.

With AI-HALS technology, ARKKY can finish in few hours the printing work which before need dozens of hours. It also improve the stability and structure strength of final product. This means consumer can much faster enjoy 3D printed shoes which are lightweight, durable and eco-friendly.

ARKKY technology leader said:

“AI-HALS technology is the key breakthrough for us to push 3D printed shoes really into mass market. It makes 3D printed shoes go from concept verification to real scale production, and also give solid foundation for personalization and sustainable manufacturing.”

With the adoption of AI-HALS technology, ARKKY plan to release more product line in future, including high performance sports form shoes, lifestyle daily ease shoes and customized printed shoes. Meanwhile, this technology will also open for cooperation, to help more footwear brands and manufacturers make digital upgrade, and together push the industry into high-speed additive manufacturing era.

About ARKKY

ARKKY is an innovative footwear brand focus on 3D printed shoes R&D and production. Through self-developed material, algorithm and printing process, ARKKY dedicate to bring new generation footwear products which combine comfort, sustainability and personalization for global consumer.

Share:

From Laboratory to Market: 3D Printed Sneakers Enter Consumer Era

Meet ARKKY on 2026 January Florida Surf Expo