In the past, to finish one pair of shoes with 3D printer often need several hours or even more than ten hours. Because of this, 3D printed shoes always stay in the stage of concept or very limited release.

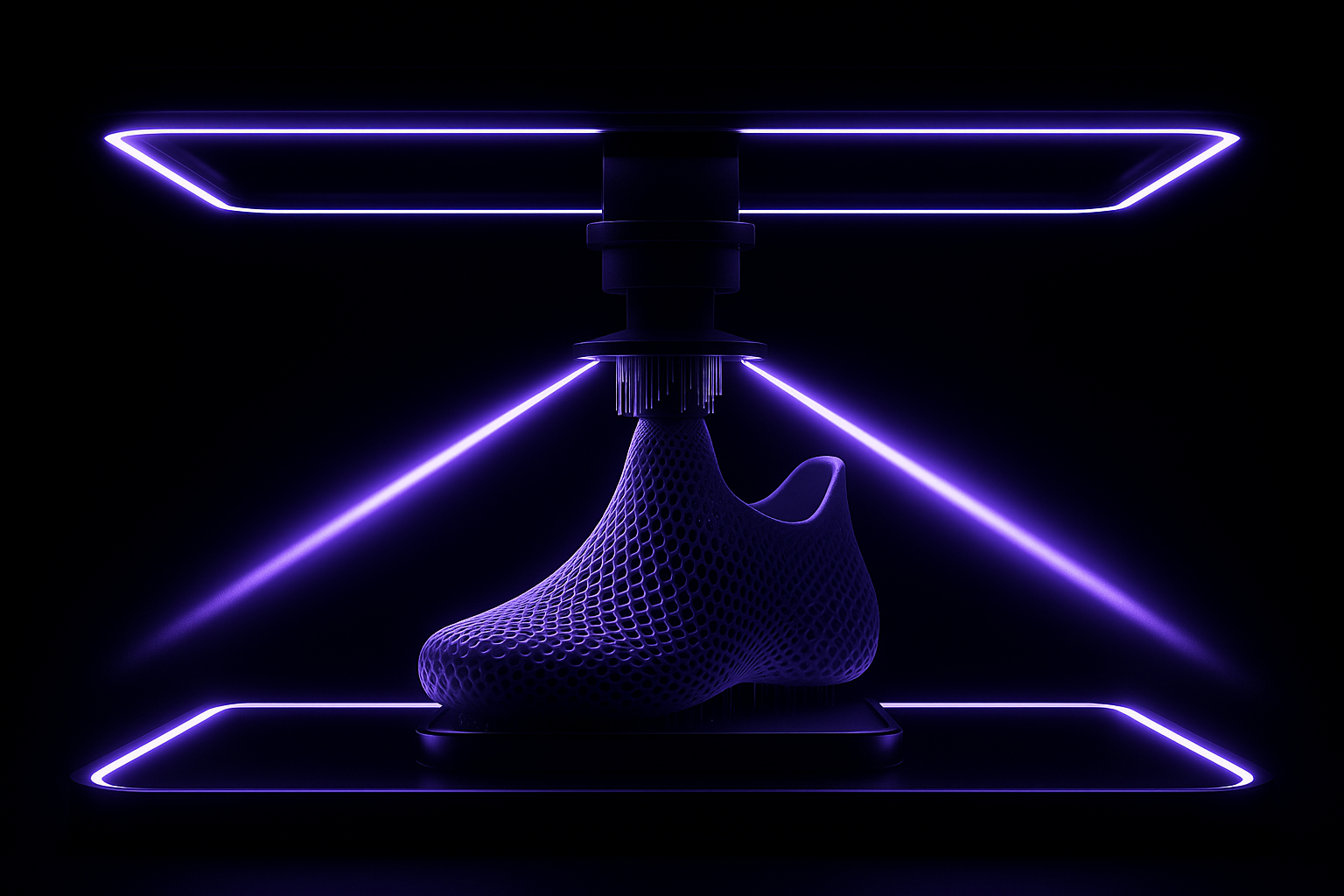

Now, with the coming of AI-HALS 3D printing technology platform (AI-Hindered Asynchronous Light Synthesis), this situation already changed completely, making shoe production become much more simple.

What is AI-HALS Technology Platform?

AI-HALS 3D printing technology platform is a brand-new way of additive manufacturing. It combines ultraviolet fast curing, hindered asynchronous curing mechanism & artificial intelligence control system together.

Its working principle can be summarized as:

- With ultraviolet light, photosensitive material can almost solidify immediately;

- Through hindered asynchronous curing, molecular chain reaction become more stable, avoid breaking or deformation;

- AI algorithm will monitor printing process in real-time, smartly allocate light energy & curing sequence, so every part can get the best performance.

Because of these synergy effects, the printing efficiency compared with traditional craft is increased 20–100 times. The time of printing one pair of shoes is shortened from several or dozens of hours to only tens of minutes.

Additive Manufacturing & Environment

Different from traditional “subtractive manufacturing” (such as cutting, grinding), 3D printing additive manufacturing use material layer by layer, only use necessary material, reduce waste from the beginning.

The environmental & energy-saving advantages of additive manufacturing include:

- High material utilization: almost no bulk waste, reduce resource wasting;

- Simpler production process: no need many complex procedures, lower energy use & pollution;

- On-demand customization: precise production reduce inventory & overproduction, meet sustainable manufacturing idea.

Besides, the “dark factory” mode promoted by AI-HALS platform save more energy: the whole production line can run under weak light or even without lighting. With high-speed automatic printing & AI scheduling, electricity consumption is largely reduced. Even daily output reach tens of thousands of pairs, the energy cost for each product still very low, achieving the goal of high capacity with low energy.

Technology Highlights

- Ultra-fast printing: time reduced from hours to tens of minutes, capacity much improved;

- Smart material control: AI accurately control UV energy, make outsole more strong & durable, upper more flexible & light;

- Stable consistency: asynchronous curing prevent deformation from heat concentration, mass products keep high quality, realize “customized mass production.”

Application in Footwear

ARKKY makes 3D printed shoes move from “experimental concept” to “daily wearing” with AI-HALS platform:

- Daily Ease series: light & comfortable, good for home & commuting;

- Sport Form series: better support & cushioning, good for sports use;

- Avant Garde series: advanced design, technology & fashion combine.

Because of this, consumers no need line up for limited sale anymore. They can directly enjoy many styles of 3D printed shoes, at the same time also support low-carbon production which bring social value.

Cooperation for Win-Win

On ARKKY AI-HALS 3D printing technology platform, every designer can easily make idea to reality. To ensure smooth cooperation & successful product release, ARKKY sincerely invite global footwear designers to join, and put forward the following ways & requirements:

Cooperation Models

- Co-branding release: designers can launch joint series with ARKKY, using double brand promotion.

- Limited series: designers can create exclusive edition, highlight personal style & ARKKY technology strength.

- Authorized cooperation: ARKKY provide AI-HALS technology license to independent designers or brands, help them grow.

Design Requirements

- Designs must be original, also fit ARKKY’s brand idea of innovation, comfort & sustainability.

- Designers need to provide digital 3D file or design draft match AI-HALS platform request.

Production & Rights

- ARKKY responsible for technology, production & quality control.

- IP rights will be clearly agreed in contract, to ensure both ARKKY & designers’ benefits.

Marketing & Promotion

- ARKKY will provide worldwide marketing support, including online promotion, fashion events & media exposure.

- Designers encouraged to use personal channel to promote together, expand influence.

Broader Meaning

The breakthrough of AI-HALS platform not only impact footwear deeply, but also means 3D printing come into real efficient industrialization era. Its potential application include:

- Medical: customized orthopedic insoles, rehabilitation support devices;

- Aerospace: lightweight structure parts;

- Consumer goods: quick personalized production of furniture & accessories.

Conclusion

AI-HALS 3D printing technology platform combine ultraviolet curing, asynchronous mechanism & AI control together, make printing speed improve 20–100 times, solve the problem of production capacity.

More important, with high material usage of additive manufacturing & energy-saving “dark factory” practice, AI-HALS give manufacturing a green path with both efficiency & sustainability. With the further progress of AI & material science, maybe we will enter the new age of “what you think is what you produce.”

Share:

3D Printed Footwear: How 3D Printing is Changing Racetracks and Runways