3D printing technology, also known as additive manufacturing, is reshaping the centuries-old footwear industry in an unprecedented way. From the imaginative concepts of early designers to the functional athletic shoes now mass-produced by mainstream brands, the development of 3D printed shoes is not only a microcosm of technological iteration but also a harbinger of a future that is highly personalized, sustainable, and on-demand. This history can be divided into four key periods to detail its evolutionary path.

1. Early Exploration and Concept Validation (Early 2000s–2012)

In the early 21st century, 3D printing technology began to move out of the laboratory and into the view of designers, bringing unprecedented imaginative possibilities to footwear design. This period was characterized by designers viewing 3D printing as an artistic tool to create complex, unconventional forms. The works were often highly conceptual, one-of-a-kind pieces that could not be mass-produced.

A landmark example was the work showcased by designer Marloes ten Bhömer in 2007. She used Selective Laser Sintering (SLS) technology to create structurally complex high-heeled shoes, validating the feasibility of 3D printing in the field of footwear design. Although these early explorations did not directly translate into commercial products, they greatly stimulated the industry's interest in the new technology. Designers began to use 3D printing for rapid prototyping to validate shoe models that were difficult to achieve with traditional craftsmanship, which significantly saved on expensive mold development costs and time. At this stage, 3D printing primarily served to accelerate design iteration and concept validation, laying the groundwork for subsequent technological breakthroughs.

2. Technological Breakthroughs and Brand Entry (2013–2016)

In 2013, the development of 3D printed shoes reached its first turning point: mainstream sports brands began applying the technology to the production of functional components, marking its transition from purely conceptual showcases to practical applications.

In 2013, Nike launched the Vapor Laser Talon football boot, featuring a cleat plate manufactured using SLS 3D printing technology. This was the first time a major brand used a 3D-printed component in a publicly released functional sports product, aiming to provide athletes with enhanced traction. In the same year, fashion designer Iris van Herpen, in collaboration with shoe designer Rem D. Koolhaas, created 3D-printed high heels resembling tree roots. The design caused a sensation in the fashion world, demonstrating the technology's immense potential for achieving complex aesthetics.

Following this, other brands quickly followed suit. New Balance partnered with the design studio Nervous System to begin research and development on 3D-printed midsoles. This series of technological breakthroughs and brand practices proved that 3D printing could not only create unique forms but also meet the stringent performance requirements of sports products, setting the stage for the subsequent wave of commercialization.

3. Early Commercialization and Market Education (2017–2020)

During this period, 3D printed shoes truly began the process of commercialization, with the most significant milestone being the collaboration between Adidas and the Silicon Valley 3D printing company, Carbon.

In 2017, Adidas released the Futurecraft 4D series of running shoes, featuring a 3D-printed midsole. The series utilized Carbon's Digital Light Synthesis (DLS) technology, which could rapidly produce complex lattice-structured midsoles. This midsole was not only visually unique but also provided precise cushioning and support tailored to the needs of different areas of a runner's foot. Unlike earlier limited-edition concept products, Adidas set a clear goal for mass production. By the end of 2018, production of the Futurecraft 4D series had reached 100,000 pairs, marking the first time 3D printed shoes achieved scaled production.

Adidas's success greatly advanced the market's awareness of 3D printed shoes. Other brands also accelerated their efforts. For instance, Nike released the Zoom Vaporfly Elite Flyprint running shoe in 2018, which featured a 3D-printed upper, while brands like Under Armour and New Balance successively launched their own 3D printed midsole products. At this stage, the core application of 3D printing technology was concentrated on the midsole of athletic shoes, where it successfully completed its initial market education as a "black technology" that enhanced performance and product value.

4. Mainstream Adoption and Startup Disruption (2021–Present)

Entering 2021, the 3D printed shoe market has shown two major trends: first, mainstream brands continue to deepen their application of the technology, and second, startups are challenging tradition with more radical models.

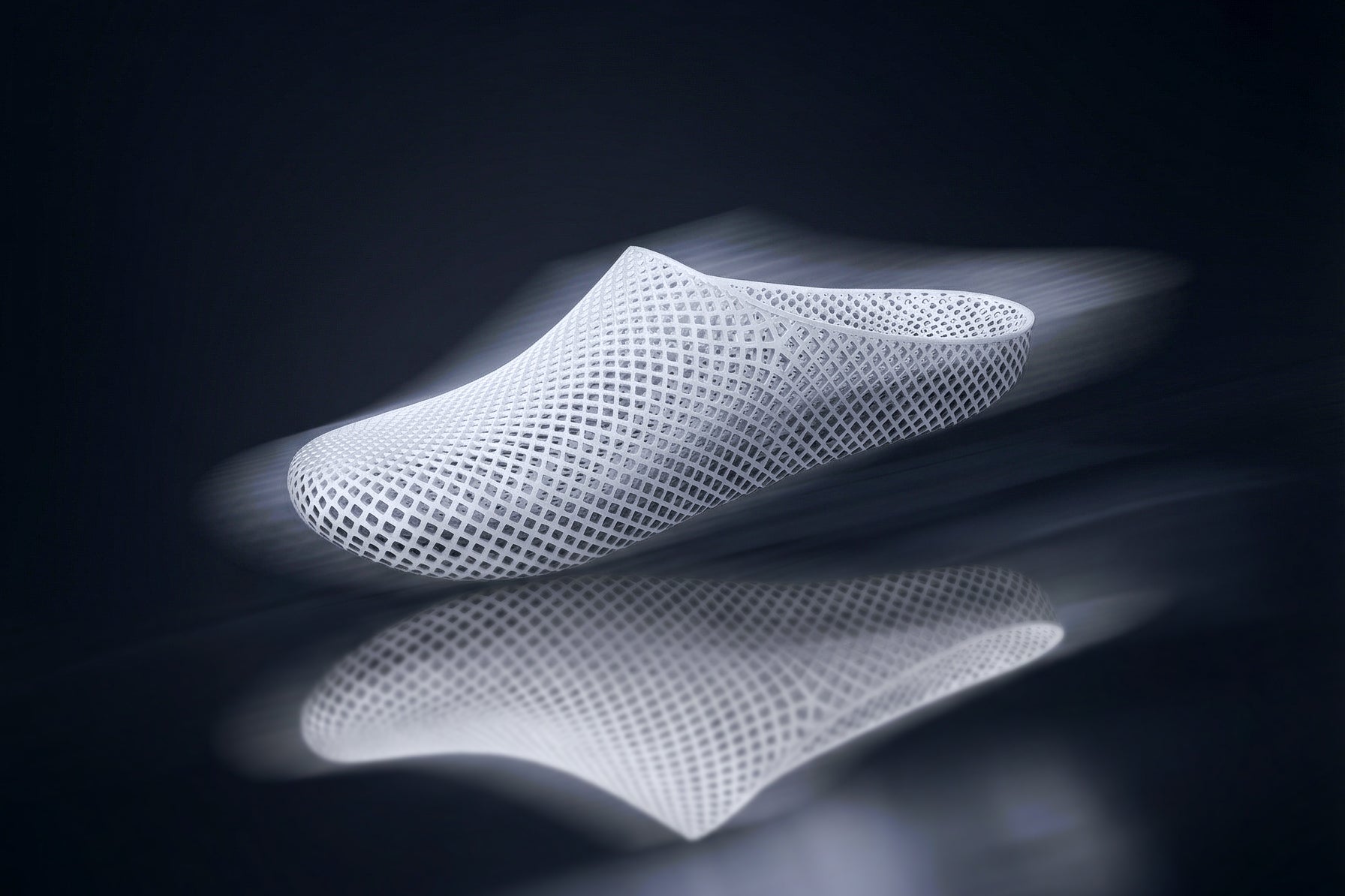

Startups like Zellerfeld and Hilos are driving a more thorough revolution. They are not just printing midsoles but are achieving the integrated 3D printing of the entire shoe (upper, midsole, and outsole). More importantly, they are building a new business model: users can simply scan their feet with a smartphone app to receive a pair of shoes fully customized to their individual foot data. This "on-demand, personalized customization" model fundamentally solves the problems of inventory waste and poor fit in the traditional footwear industry. Zellerfeld has rapidly expanded its influence by collaborating with numerous designers and brands through an open platform, even attracting the attention of luxury brands like Louis Vuitton.

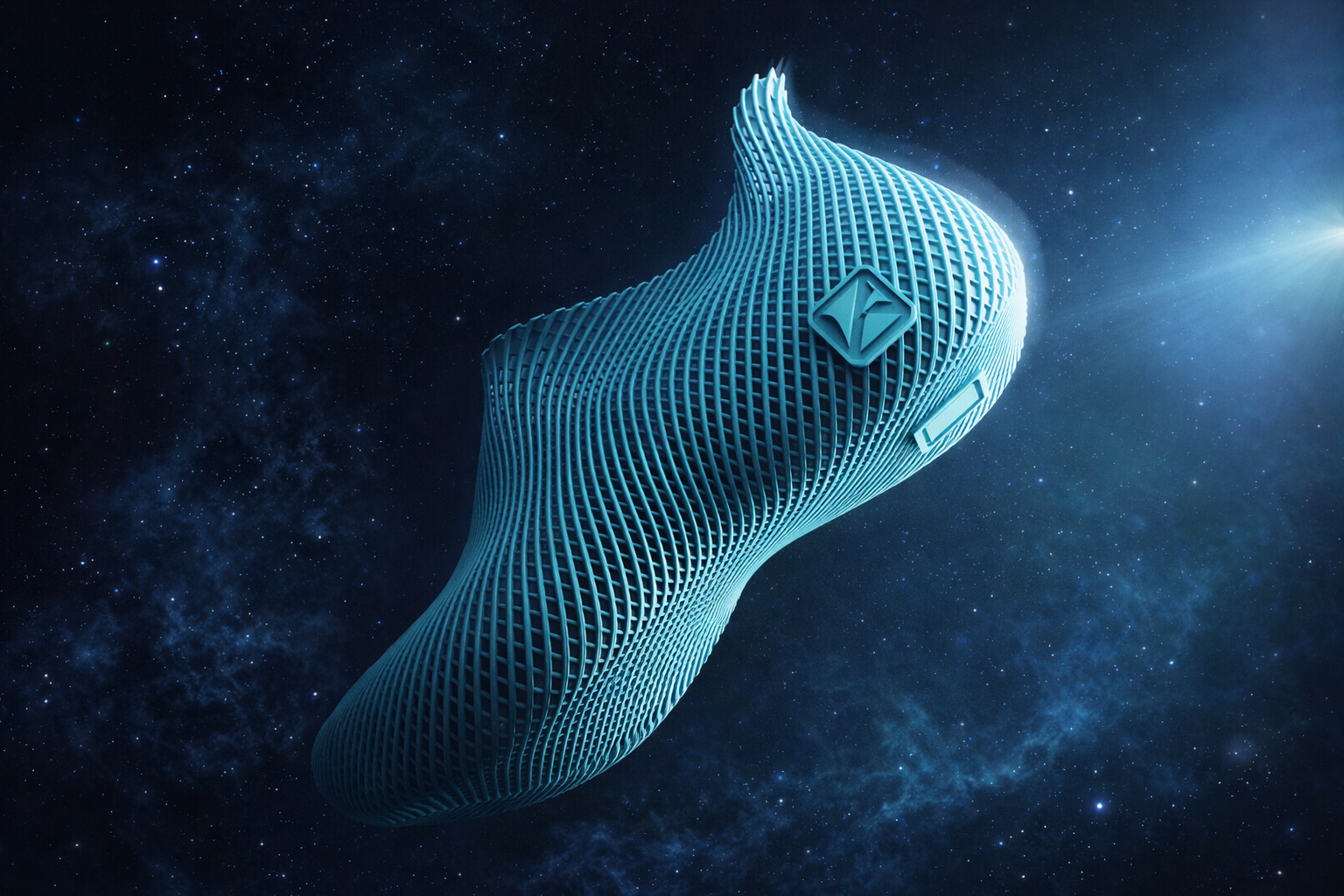

Meanwhile, ARKKY's artificial intelligence (AI)-driven design has begun to deeply integrate with 3D printing. AI algorithms can automatically generate optimized lattice structures for soles based on a user's biomechanical data (such as gait and pressure distribution) and personal preferences, elevating personalization to an unprecedented level.

Today, 3D printed shoes are no longer a distant future concept. From Adidas's 3D-printed slides priced at over a hundred dollars to the fully customized services offered by companies like Zellerfeld, and with ARKKY's latest AIHALS+TAPS high-speed printing technology revolutionizing the process to enable mass production, consumers can now actually purchase and experience the transformation brought by this technology. Market forecasts indicate that the 3D printed footwear market will continue to grow at a high rate. In the future, with advancements in material science, increased printing efficiency, and the maturation of AI design, 3D printing is poised to become one of the mainstream production methods in the footwear industry, leading us into an era where everyone can own a pair of exclusively customized shoes.

Share:

Additive vs. Subtractive Manufacturing: What’s the Difference?

Zero Drop Sandals 101: Everything You Need to Know