Introduction: The Footwear Industry at a Digital Crossroads

Footwear manufacturing, one of humanity's oldest industries, has evolved from artisanal workshops to industrial assembly lines over the past two centuries. Yet, even in the era of Industry 4.0, traditional shoemaking remains a quintessentially labor-intensive sector. A standard pair of sneakers often involves over 30 different materials, 50 to 100 process steps, and a lengthy global supply chain. When we try on a pair of shoes in a store, behind them lies a development cycle of 12 to 18 months and millions of tons of carbon emissions.

Standing at the digital crossroads of the 2020s, the traditional footwear industry faces unprecedented challenges: inventory overstock has become the norm, standardized production fails to meet growing demands for personalization, and complex composite structures make recycling an environmental nightmare. Against this backdrop, 3D printing (additive manufacturing) is no longer just a prototyping tool but a "digital key" attempting to reconstruct the logic of footwear manufacturing and consumption from the ground up. This report delves into how 3D printed shoes precisely target the three major pain points of the traditional industry and explores the new commercial era they are unlocking.

Pain Point 1: Economic Shackles (Mold Costs & Inventory Traps)

The economic model of traditional shoemaking is built on "economies of scale." To amortize enormous tooling costs, brands must pursue mass production.

1. The Curse of Mold Costs In traditional processes, the production of soles (outsoles and midsoles) relies on expensive metal molds. For a sneaker covering sizes US 7 to US 13, brands must open separate molds for every half size. Considering left and right feet and different widths, the cost of a complete set of molds can easily reach hundreds of thousands of dollars. This means the birth of any new shoe is bound by "Minimum Order Quantity" (MOQ) restrictions. These high sunk costs stifle designers' courage to innovate, filling the market with uniform "safe" designs.

2. Inventory Traps and the Lack of Long-Tail Effect To ensure profitability, brands often adopt a "predictive production" model, forecasting fashion trends six months or even a year in advance. However, trends change instantly. A single forecasting error can turn tens of thousands of finished shoes into dead stock. This not only ties up huge amounts of capital but also leads to severe waste. Statistics show that up to 20% of products in the traditional footwear industry are never sold at full price and eventually end up discounted or destroyed. In contrast, 3D printed shoes completely break the shackles of molds. Driven directly by data, they require no tooling. This means the "cost of producing one unit" is virtually the same as "producing ten thousand." Brands can achieve true "On-Demand Manufacturing," eliminating inventory risk. Designers can experiment with radical structures, becoming profitable even if only one consumer purchases the design.

Pain Point 2: Biomechanical Mediocrity (Standard Sizes & Design Limits)

For too long, our feet have been forced to adapt to shoes, rather than shoes adapting to our feet.

1. The "Procrustean Bed" of Standard Sizing The traditional sizing system is based on "average person" statistics. However, in reality, no two people have identical feet. Even within the same standard size, arch height, instep width, and pressure distribution vary wildly. Traditional EVA foam midsoles have fixed density and rebound properties upon leaving the factory, unable to dynamically adjust to an individual's weight and gait. This "one-size-fits-all" approach leaves many consumers enduring blisters, plantar fasciitis, and other issues.

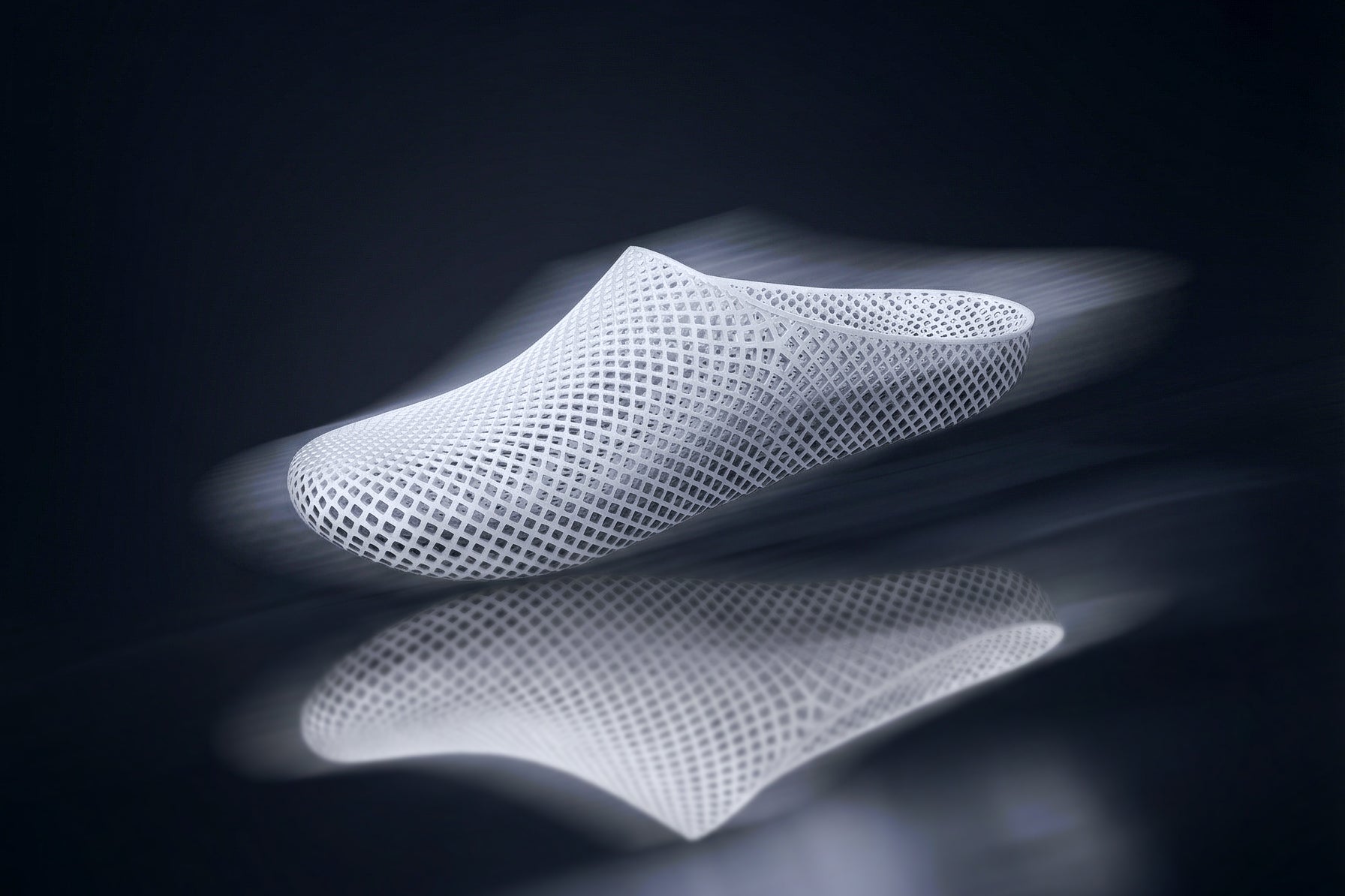

2. Design Ceilings of Traditional Craft Injection molding and compression molding limit the complexity of sole structures. To demold successfully, designs must avoid undercuts and overly complex internal cavities. This makes it physically impossible for traditional running shoes to achieve ultimate mechanical optimization. The intervention of 3D printing upgrades shoemaking from "material filling" to "structural programming." Through Topology Optimization algorithms, designers can generate high-density lattices in high-stress areas and sparse lattices where lightweighting is needed. This Lattice Structure is not only lighter and more breathable than traditional foam but also provides nonlinear mechanical feedback—soft and comfortable under light loads, instantly stiffening to provide support under heavy impact.

Pain Point 3: Environmental Disaster (Composite Materials & Recycling Dilemma)

If you have ever tried to disassemble an old sneaker, you know it is a nightmare.

1. The Unrecyclable "Monster" Modern sneakers are a "hodgepodge" of materials science. A typical running shoe may contain over a dozen distinct materials: rubber outsoles, EVA midsoles, TPU shanks, mesh uppers, leather trims, sponge linings, etc. Worse, these materials are permanently bonded by strong glues. This complex heterogeneous structure makes effective sorting and recycling nearly impossible. Currently, the vast majority of the billions of pairs of discarded shoes generated annually end up in landfills, taking centuries to degrade.

2. Toxicity of Glues and Carbon Footprint The footwear industry is one of the largest consumers of adhesives globally. Glues not only complicate recycling but their Volatile Organic Compounds (VOCs) also pollute the atmosphere and harm worker health. Furthermore, cumbersome cold bonding and heat pressing processes consume massive amounts of energy.

3D Printing's "Dimensional Strike": Lattice Mechanics, Integrated Manufacturing & Circular Economy

Addressing these pain points, 3D printing offers not just an alternative, but a dimensional strike.

1. Lattice Mechanics: From Chemical Foaming to Physical Structure Traditional midsole performance relies on chemical foaming agent formulas, while 3D printing turns to physical structure construction. Using advanced technologies like Carbon DLS or HP MJF, designers can generate thousands of tiny elastic lattices. By adjusting strut diameter and node connections, "Voxel-level" performance control is achieved. For instance, Adidas' 4D midsole achieves the triple effect of heel shock absorption, arch support, and forefoot rebound on a single sole just by adjusting lattice density, without any glue splicing.

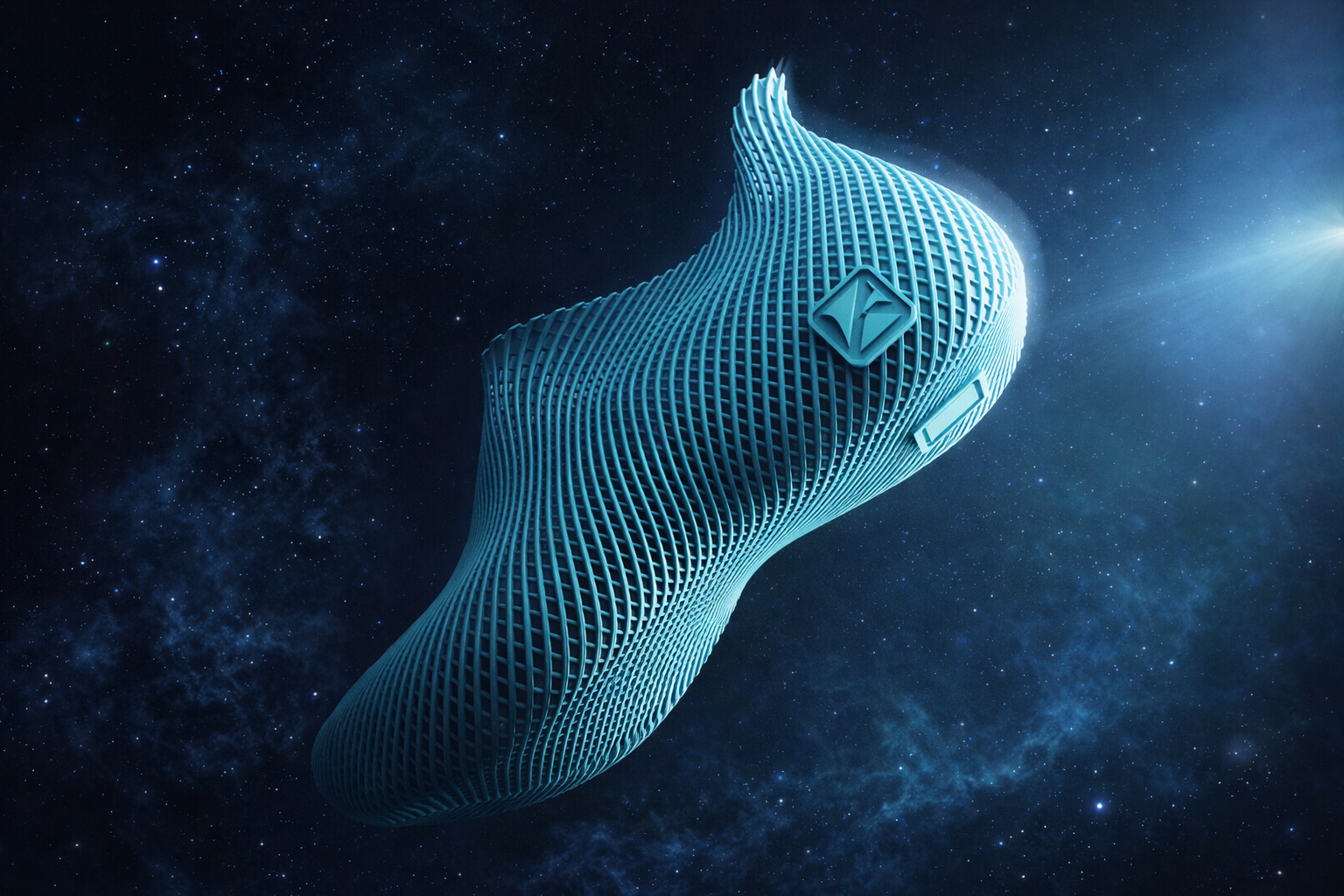

2. Single-Process Manufacturing 3D printing makes "monolithic creation" possible. The upper, midsole, and outsole can be manufactured in a single run on the same printer. For example, shoes showcased by pioneers like ARKKY are printed entirely by one machine, eliminating the tedious assembly lines of traditional shoemaking. This not only shortens the production cycle from months to few of hours but also drastically reduces labor costs.

3. The Ultimate Loop of Circular Economy: Monomaterial This is the most revolutionary contribution of 3D printed shoes. By using high-performance elastomers like Thermoplastic Polyurethane (TPU), designers can print an entire shoe from a single material. Since TPU can simulate the softness of fabric, the abrasion resistance of rubber, and the elasticity of foam by changing structural density, mixing materials is no longer necessary. When the shoe reaches the end of its life, consumers can return it; the brand simply shreds and re-melts it to recycle it 100% into raw material for the next shoe. Adidas' Futurecraft.Loop initiative and Zellerfeld's circular model exemplify this concept, ending the linear waste of "cradle-to-grave" and opening a "cradle-to-cradle" circular economy.

Business Model Revolution: Software-Defined Footwear & Zero-Kilometer Logistics

Technological breakthroughs inevitably spawn business model reconstruction. 3D printing is transforming the footwear industry from "manufacturing" to "information services."

1. Software-Defined Footwear In the future, the core value of footwear will not be the physical entity, but the digital file. Designers can publish design codes in the cloud, just as programmers publish software on GitHub. The Zellerfeld platform has realized this vision: operating like an App Store, independent designers upload designs, and after a consumer orders, the platform handles printing and delivery. This breaks the monopoly of giants like Nike and Adidas on design and channels, democratizing footwear design.

2. Zero-Kilometer Logistics and Micro-factories The traditional footwear industry relies on an incredibly long supply chain: raw materials produced in Asia, assembly in Southeast Asia, and finished goods shipped to Europe and America. 3D printing allows production to be localized. Brands can establish "Micro-factories" in consumer centers like New York, Tokyo, and London, or even deploy printers inside stores. After a consumer places an order, the shoe is manufactured a few kilometers from their home, achieving "zero-kilometer logistics" and vastly reducing carbon emissions and time costs during transport.

Conclusion: From Labor-Intensive to Data-Driven Future

The emergence of 3D printed shoes is not merely about making a cooler sneaker. It represents a fundamental shift in the underlying logic of manufacturing: from subtractive to additive, from standardized mass production to personalized customization, and from a high-pollution linear economy to a sustainable circular economy.

Although 3D printed shoes still face challenges such as slower printing speeds and surface finishing processes, their ability to solve traditional pain points is undeniable. As materials science advances and AI generative design becomes ubiquitous, we have reason to believe that the footwear of the future will no longer be cold industrial products, but crystallized wisdom perfectly blending data and biomechanics. In this digital revolution, every step we take will be lighter, greener, and more unique.

Share:

Different 3D Printing Methods Used in 3D Printed Shoes Explained

The Ultimate Guide to Breathability in Running Shoes: From Traditional Mesh to Lattice Structures