Introduction Standing at the juncture of 2026, when we walk into the flagship store of any top sports brand or browse digital fashion platforms, we find that the protagonists on the shelves have quietly changed. The complex lattice-structured shoes that were once displayed as concept products now occupy the center stage. This is the most thorough technological revolution in the shoe making industry since the introduction of EVA (Ethylene-Vinyl Acetate) foam materials in the 1970s.

For a long time, the manufacturing logic of traditional sneakers has been one of "subtraction" and "assembly": cutting leather, vulcanizing rubber, injection molding foam, and finally gluing dozens of parts together. While this model is mature, it carries a heavy price: exorbitant mold costs (a single sole mold can cost thousands of dollars), a supply chain cycle as long as 18 months, and unavoidable environmental guilt.

In 2026, with the maturation of ARKKY's AIHALS technology, Zellerfeld's GEN3 platform, and the deep deployment of traditional giants like Adidas, ASICS, and Peak, 3D printed shoes have finally crossed the chasm of "cost" and "efficiency." Consumers now face a brand-new choice: stick with the familiar traditional sneakers pressed from molds, or embrace a pair of digital footwear generated by algorithms and solidified from light and powder? This article will provide a detailed comparative analysis from the dimensions of technology, performance, price, and sustainability.

Brand & Technology Deconstruction

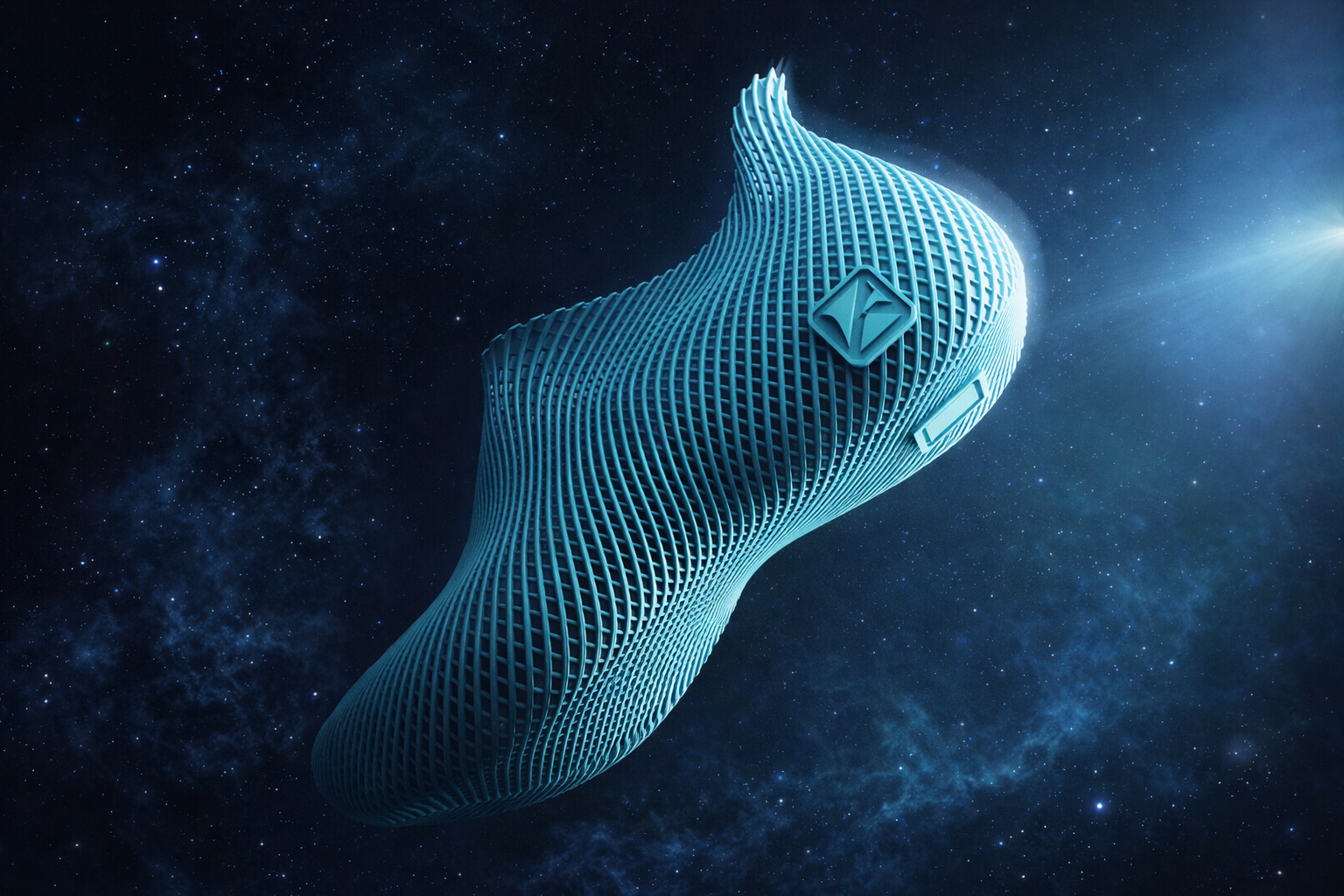

ARKKY: The Speed Revolution of AIHALS

in the 2026 market,ARKKYis undoubtedly the most disruptive dark horse. Its core weapon is the AIHALS (AI Inhibited Asynchronous Light Synthesis) technology. Unlike early layer-by-layer methods, AIHALS uses AI algorithms to dynamically control the light field and oxygen inhibition layer on the surface of liquid resin, achieving an effect similar to "growing directly from liquid."

- Technological Advantage: This technology increases printing speed by 20-100 times, compressing the printing time of a shoe midsole to mere minutes. More importantly, it completely eliminates layer lines, making the shoe surface as smooth as injection molding, and the material possesses isotropic mechanical properties.

- Representative Product: AeroDash series. This series uses AI-calculated non-uniform lattice structures to achieve different hardness levels on the same material—soft at the heel for shock absorption and rigid at the arch for support.

Zellerfeld: The GEN3 Mono-Material Platform

Zellerfeld has become the "YouTube of footwear" in 2026, with its GEN3 printer being the core carrier of open design.

- Technological Advantage: GEN3 focuses on a variant of FDM (Fused Deposition Modeling) technology but with extremely high precision. Its killer feature is the Mono-material concept. The entire shoe is printed in one piece from a single thermoplastic material (usually modified TPU), without any glue or stitching. This means that after the shoes are worn out, they can be 100% recycled, shredded, and directly used to print the next pair.

- Market Position: It does not produce "Zellerfeld brand" shoes but allows global designers to publish designs on its platform, which are printed immediately upon consumer order. This model completely eliminates inventory.

Adidas: The Evolution of Carbon DLS

As a pioneer in 3D printed shoes, Adidas, in partnership with Carbon, has mastered DLS (Digital Light Synthesis)technology by 2026.

- Technological Advantage: Adidas's strength lies in data accumulation. Using decades of athlete data, the 4DFWD lattice midsole they designed can convert vertical impact forces into forward propulsion. Carbon DLS technology uses light-curing resin to print lattice structures with extremely high energy return and durability, far surpassing traditional EVA foam.

- Product Positioning: Adidas firmly locks 3D printing technology in the "high-performance competitive" field, rather than just fashion items.

Peak & ASICS: The Maturity of SLS

Peakand ASICS represent two major application directions of SLS (Selective Laser Sintering) technology.

- Peak (China): Using SLS technology to print TPU powder, Peak successfully reduced the cost of 3D printed shoes to a range acceptable to the mass market (approx. $150-$190). Its "Future Fusion" series proved the feasibility of fully 3D printed shoes in high-intensity sports like basketball.

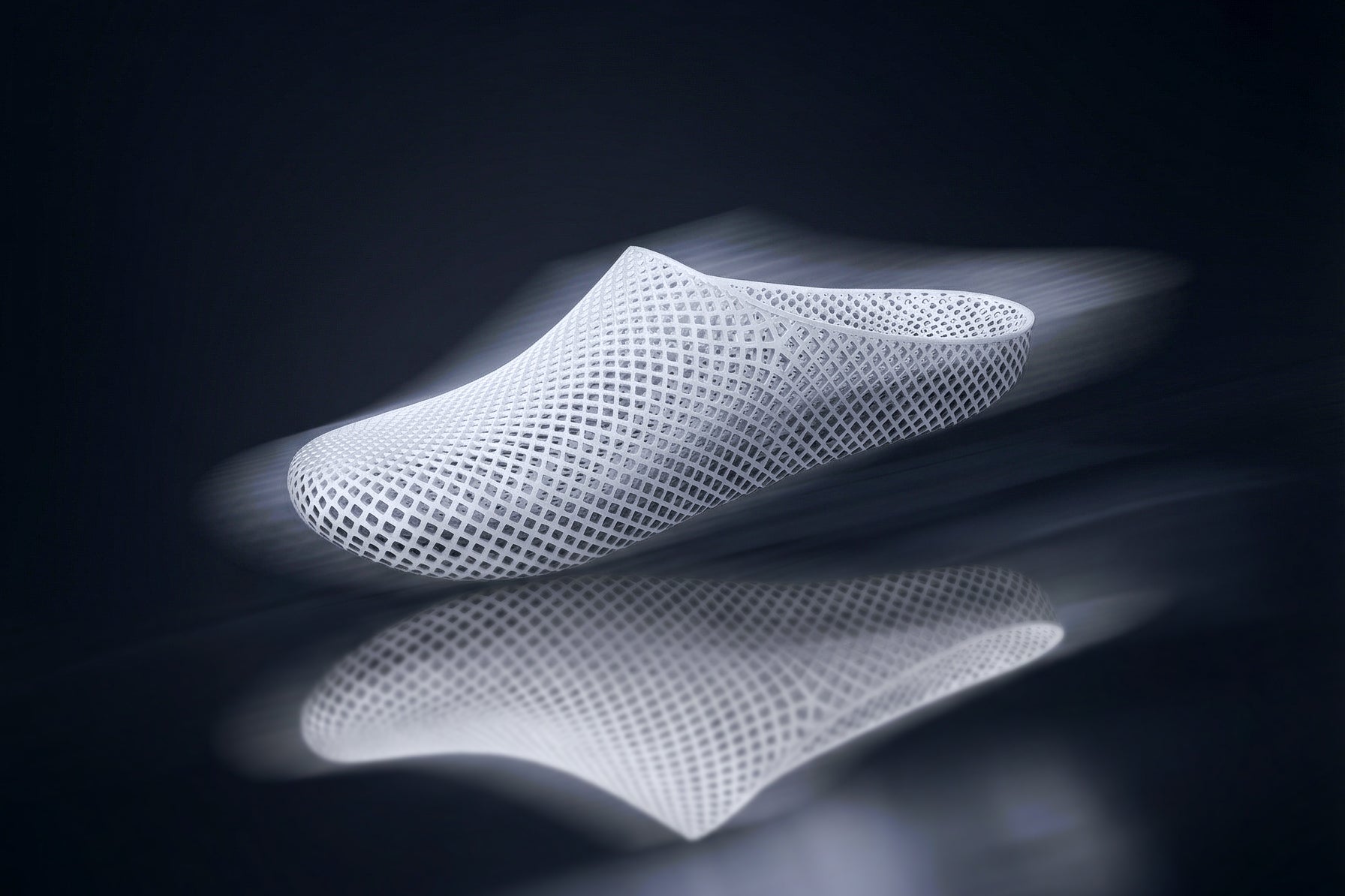

- ASICS (Japan): ASICS focuses on "recovery" and "breathability." Its Actibreeze 3D slides use SLS technology to create breathable grids with ultra-large apertures, designed specifically for athletes' post-race relaxation. Priced at only about $80, it is one of the most cost-effective 3D printed footwear options on the market today.

The Deep Dive Showdown

Performance: Lattice vs. Foam

Traditional Sneakers: Rely on the chemical properties of EVA or ETPU (like Boost) foam materials to provide cushioning.

- Drawback: Materials undergo "compression set." With every step, the foam walls are damaged. After about 300-500 kilometers, cushioning performance decays by 30%-50%, and the feel becomes hard.

3D Printed Sneakers: Rely on the deformation of physical structures (Lattice) to store energy.

- Advantage: Test data from ARKKY and Adidas show that the fatigue resistance of high-performance resin lattices is 3-5 times that of traditional foam. Even after 1000 kilometers of use, their mechanical resilience shows almost no decay.

- Breathability: The open mesh structure of 3D printing completely solves the heat dissipation problem, achieving "breeze underfoot," which is incomparable to traditional closed-cell foam midsoles.

Price Comparison (2026)

|

Category |

Brand Example |

Price Range |

Notes |

|

Traditional Flagship |

Nike Alphafly, Adidas Adizero |

$250 - $300 |

Premium mainly from branding and complex supply chain |

|

Traditional Mid-Range |

ASICS Kayano, Nike Pegasus |

$120 - $160 |

High value, but limited lifespan |

|

3D Printed Slides |

ASICS Actibreeze |

$80 |

Entry-level experience, extremely high value |

|

3D Printed Performance |

ARKKY |

$99 - $250 |

AIHALS technology lowered costs; matches traditional mid-range prices with high performance |

|

3D Printed Designer |

Zellerfeld(Collabs) |

$200 - $350 |

Focus on customization and scarcity, slightly higher price |

Conclusion: In 2026, 3D printed shoes are no longer prohibitively expensive. Especially products from ARKKY and Peak have entered the mainstream price range of traditional sneakers ($100-$250).

Sustainability: The Mono-Material Victory

This is the weak point where traditional sneakers cannot argue back. A traditional pair of Air Jordans may contain over a dozen materials like leather, nylon, rubber, foam, and plastic sheets, bonded by strong glue. To recycle it, manual disassembly is required, which is extremely costly, so the vast majority end up in landfills.

3D Printed Shoes (especially Zellerfeld and ARKKY)adopt a Mono-material strategy. The entire shoe is made of a single polymer.

- Circular Logic: User wears out the shoes -> Ships back to factory -> Machine shreds -> Re-melted into raw material -> Print new shoes.

- Zero Waste: No cutting scraps, no unsold inventory backlog. This is true closed-loop manufacturing.

Supply Chain: Mold-Free vs. Tooling

The traditional shoe making industry is a "slave to molds." Developing a new sole requires opening steel molds for all size ranges, investing hundreds of thousands of dollars, and taking months. This leads brands to hesitate in trying radical designs and forces them to mass-produce to amortize mold costs.

3D Printed Shoes achieve "Tooling-free" manufacturing.

- Design Freedom: A designer modifies the CAD file in the morning, and a new shoe can be printed in the afternoon.

- Inventory Revolution: Zellerfeld and ARKKY adopt an "On-demand" model. No warehouses, no backlog. This not only reduces storage costs but also allows consumers with niche sizes (like extra large or small) to buy shoes at normal prices.

Buying Advice: How to Choose?

Based on the market situation in 2026, here is our buying advice:

If you are a Serious Runner:

Recommendation: Adidas 4DFWD series or ARKKY AeroDash.

Reason: You need precise energy return and support. Adidas's 4D structure is field-proven, while ARKKY's AIHALS technology offers an excellent lightweight experience. Compared to traditional running shoes, they maintain performance better after long distances.

If you are a Trendsetter or have Wide/Special Feet:

Recommendation: Designer models on the Zellerfeld platform or ARKKY AeroBB.

Reason: You can scan your feet with your phone to get a pair of Custom-fits hoes. No need to worry about pinching, and the design is absolutely unique, guaranteeing 100% head-turning rates on the street. The ARKKY AeroBB does not offer scan-based customization; it is a shoe with a bold, futuristic design.

If you seek Ultimate Breathability & Recovery:

Recommendation: ASICS Actibreeze 3D Sandal Or the Daily Ease Slippers series from ARKKY

Reason: Top-tier breathability for $90 makes it the best companion for summer or post-workout recovery.

If you are Eco-conscious:

Recommendation: Zellerfeld or ARKKY.

Reason: The fully circular recycling system frees you from the psychological burden of wearing shoes. Sending them back when worn out is a cool lifestyle in itself.

Conclusion

3D printed sneakers are no longer a concept of the future, but a choice of the present in 2026. They are not meant to completely replace traditional sneakers overnight (just as EVs didn't replace ICE cars instantly), but they offer a superior dimension: a higher performance ceiling, a more sustainable lifecycle, and a more human-centric customization experience.

When price is no longer a barrier and performance has surpassed traditional foam materials, we have no reason to refuse this revolution underfoot. It is time to take off those old injection-molded shoes and put on a future woven from light and data.

Share:

How to Choose the Right 3D Printed Shoes for Your Lifestyle